Right GPS not able to receive satellite information. On this aircraft the right antenna is forward mounted.

Kalitta/DHL hangar going up in the background.

Right GPS not able to receive satellite information. On this aircraft the right antenna is forward mounted.

Kalitta/DHL hangar going up in the background.

When you have a history of air/ground faults..... would a loose bracket holding the tilt proximity switches be a problem?

Wouldn't it be best if the sensors were actually "in" the duct?

The crap I'm finding on a weekly basis is disheartening to say the least!

Duct broken, sensors laying on ceiling light.

Heat from light caused a "Duct Overtemp" warning from tripping the high temp bulb.

Pressure Switch fault ball showing on inbound "Stabilizer Trim" EICAS message.

What is the fault ball saying?

The Stabilizer Trim/Aileron Lockout boxes verify they have two viable hydraulic systems (in this case left and center), by comparing on-side to off-side pressure switch signals. This is the left box, so it looks at the left pressure as on-side and center as off-side.

The right box would look at the center hydraulic system as on-side and the left as off-side.

Either way...... there's a mismatch. The meter confirmed this to be true. With hydraulic pressure applied to left and center, only one (of two) input pins showed a ground (both should have).

The left pressure switch was at fault.

We shot the switch by pinning directly into it. No issues.

We verified wiring..... Pin 3 was showing a hard ground. Pin 2 wasn't.

No frickin way. Sure as shit, pins 2 & 3 where swapped in the plug.

This pressure switch feeds numerous other units which are looking for the same ground signals. All six spoiler boxes, the yaw dampers, and rudder load limiters.

It also plays a roll in automatic functions of the hydro pumps and the overhead low pressure lights.

How in the ---- wasn't there some other issues with the aircraft???

Too tired to follow them all out. Either way, after the wiring was corrected, all systems (that we knew of) checked out.

Correct wiring verified by wire numbers.....

..... and continuity checks from the P37 panel.

With the pins in wrong positions, with no pressure - the grounds were correct. With pressure, both pins on the unit had continuity to each other. I really just don't know how anything worked right!

When the wing of a larger aircraft (A330) smacks the tail of a smaller one. They both lose..... one though, hurts worse.

Not sure if this is repairable.

Captain's pitot heat fail light on after engine start.

Please reference https://rotate.aero/forum/767-ice30/242-ata-30-31-pitot-heat for an understanding of the 767's pitot heat system.

The system has two heat modes, low heat after engine start and high heat in air mode.

This particular problem (failed Capt's Pitot Heat) showed up after engine start.

Pitot heat test from the P61 panel was normal.

I took out the Current Sense relay (K241) and shot the probe coil from "Pin C1". 38 Ohms..... seems normal?? Pulled the "A Phase" breaker..... still had continuity..... not normal.

What the hell is going on here?

90% of pitot heat failures are heater coils burning open. This one tested from the cockpit test switch, so the coil is still good.

Well kinda..... In test mode, you're simulating "air" mode or high heat. "A" and "B" phases are connected through the heater coil in air mode, instead of "A" phase to ground in "low heat" mode.

We pulled the probe and shot it with VOM. We found out one side of the coil wire was shorted to ground and the other completely open.

That would explain our problem. In low mode, "A" phase was going nowhere (open leg on coil), In high heat mode, "B" phase was coming in from the opposite side, going through the coil to ground. It was enough current to turn off the fail light. The pitot probe would of been heated in the air, but only in low heat mode.

I have never seen a probe fail in such a manner.

Red represents short to ground. Green, the open pin.

I wish I could show the whole circuit, but Boeing has been watching the site for plagiarism.

These tiny-ass screws hold these tiny-ass relays. I seem to drop them regularly.

These little guys are everywhere in the electronic panels down in the E&E.

Once you drop one..... you rarely ever find it.

I have looked through the IPC's. If there is a part number, I can't find one.

When you have passed the 90% timeline in your career and "then" you find out about a trick that could have saved you hours of work and struggle.....

High-density rack pins can be an absolute pain to install. Fighting wire bundles, tie-wraps, and small spaces to get your hands into.

Tweasers, needle-nose plyers, and plastic insertion tools as your weapons.

Is there an easier way?

Yep.

20 gauge wire..... strip, but don't remove insulation.

Shove through the rack socket from the front side and pull out the back.

Insert your pin in the insulation.

Pull from the front side..... the new pin locks into the plug and your wire pulls off the end!!!

Damn..... something so simple and I just find out now.

New forum post.

APU Oil Quantity Simulation

Please visit the furum under 767 APU Oil Qty Simulate.

I'm sure this is probably the same oil quantity system on most Boeing jets.

New member "rwm1273"

If someone has a website I'm more than happy to promote it

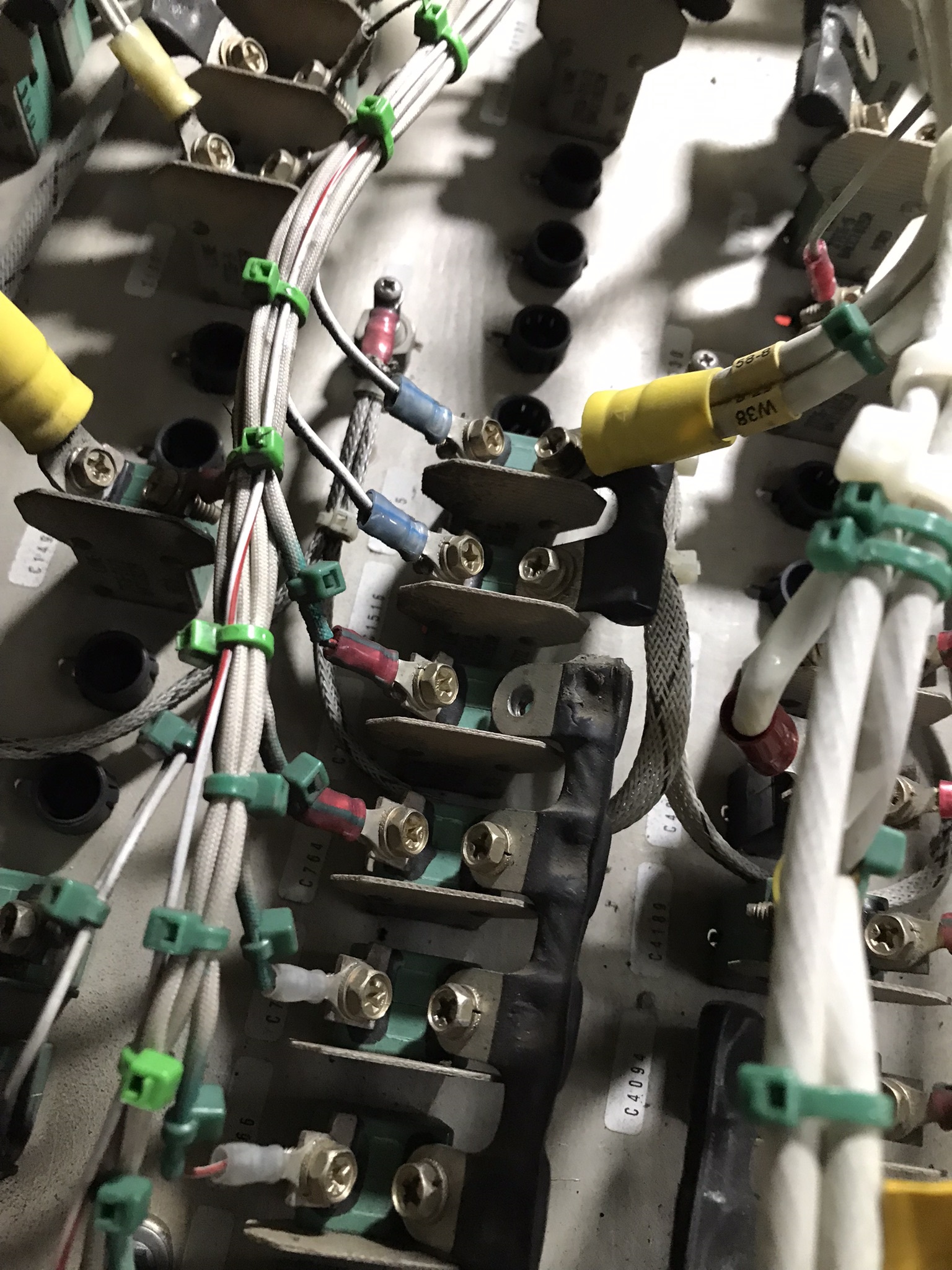

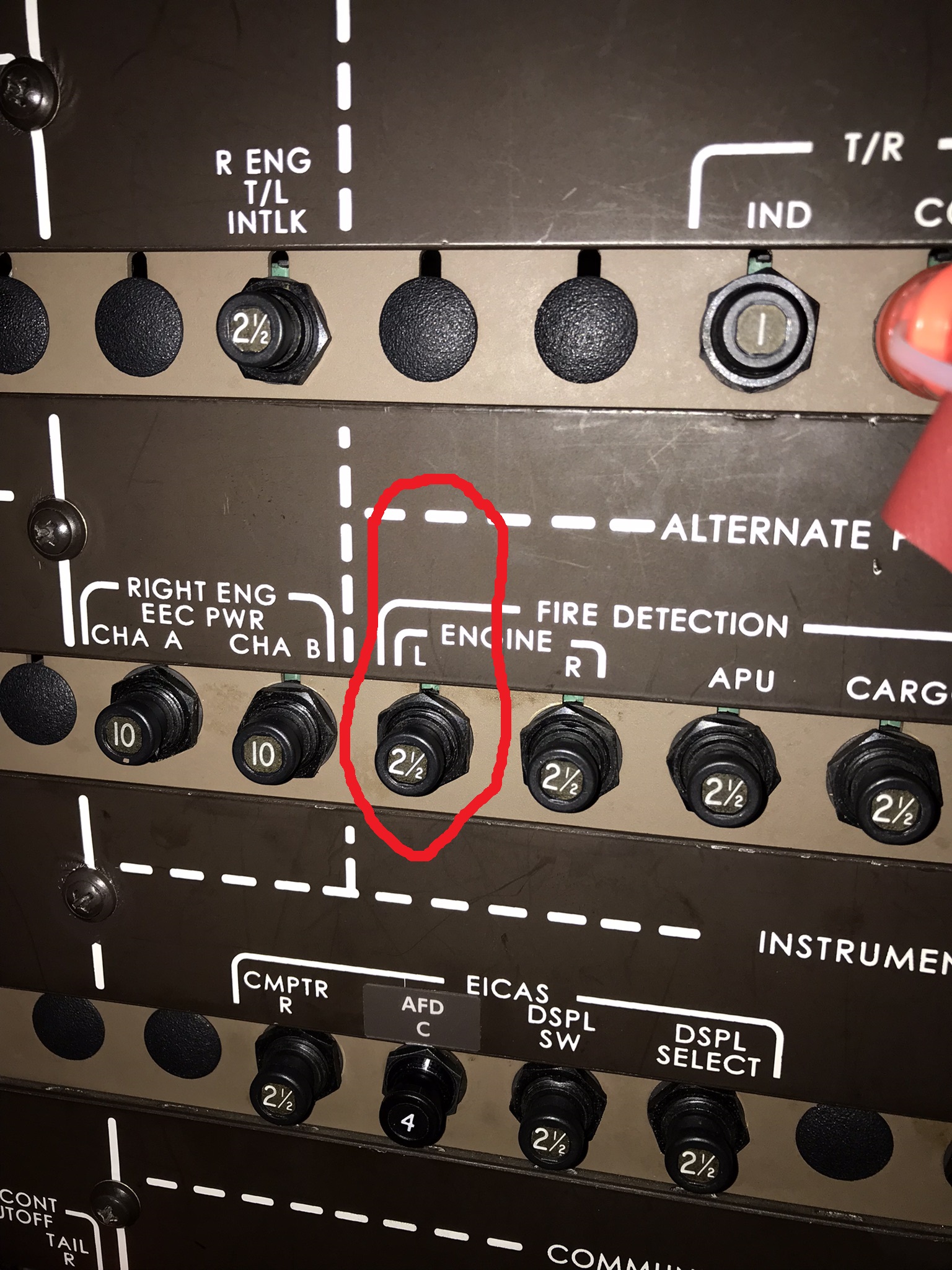

Doing a wiring modification. Some of the cockpit overhead breaker panels down. What do I see?

Missing screw on bus-bar. Not good.

System involved..... Fire detection left engine alternate power.

This would not be seen by the crew or maintenance when doing fire system tests as it is not the primary source of power. If you were in an emergency on Standby Power, fire warning would not work

From Zero Hedge

"Serious Public Safety Risk": New Boeing Whistleblower Warns About "Substandard Manufacturing" On 787 Jets

By Tyler Durden

In the first five months of this year, the Federal Aviation Administration received more than eleven times as many Boeing whistleblower complaints compared to all of last year. The surge in whistleblowers first came after the 737 Max mid-flight door plug blowout in January. The latest Boeing whistleblower was revealed on Wednesday, warning about 787 Dreamliners.

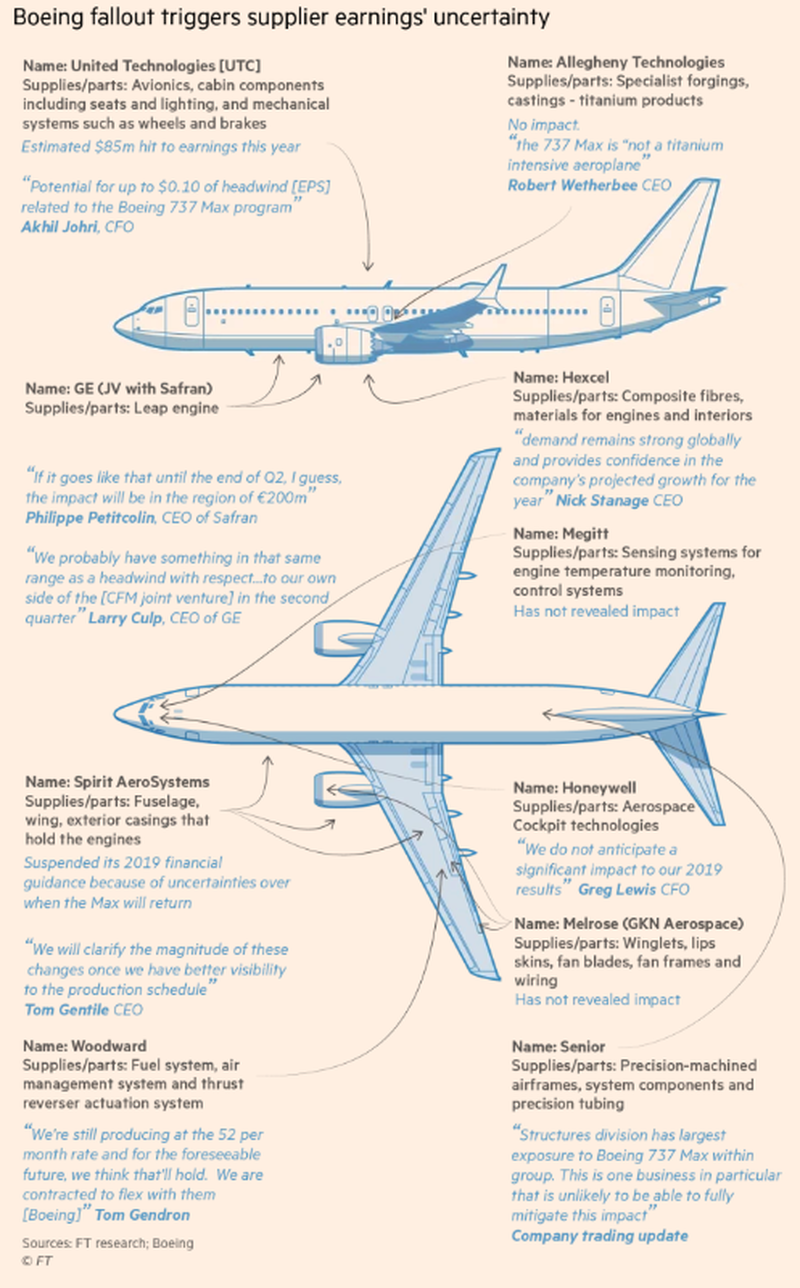

Attorneys for Richard Cuevas, airplane mechanic and contractor for Boeing manufacturing partner Spirit Aerosystems, detailed in a statement on Wednesday that they filed complaints with the FAA and Occupational Safety and Health Administration, alleging that the mechanic "witnessed substandard manufacturing and maintenance processes on the 787 forward bulkheads, including critical drilling and sealant issues."

"Cuevas complained that these safety issues, if unremedied, could compromise power and air pressure on the planes, creating a serious public safety risk," attorneys Debra Katz and Lisa Banks at law firm Katz Banks Kumin wrote in the statement.

After he brought up these troubling concerns—initially with Spirit management and later with Boeing's ethics program—he was fired. A Spirit manager told him his termination was a "sign of the times."

The lawyers continued, "Our client witnessed critical issues with the forward pressure bulkhead assembly on multiple planes that deviated from Boeing's specifications," adding, "He recognized the substandard work and expressed concern about his safety concerns, but Spirit and Boeing failed to stop the faulty manufacturing processes. Mr. Cuevas was fired when his manager found out that an employee complained about these issues, and suspected that employee was Mr. Cuevas."

Here's a summary of Cuevas' technical allegations (courtesy of his lawyers):

Mr. Cuevas's complaints allege that Spirit made a range of manufacturing and assembly specification changes on the 787 forward pressure bulkhead without Boeing's permission. These allegations are different from previously reported issues with the forward pressure bulkhead in 2021.

Mr. Cuevas alleges that Spirit deviated from Boeing's manufacturing specifications while drilling holes in the fasteners of the forward pressure bulkhead of 787s. Deviations from these specifications compromise the seal necessary to maintain air pressure during flight. Boeing requires fastener holes in this section of the plane to be drilled at .2475 inches, which provides a near-perfect "interference-fit" that best retains air pressure during flight. Instead of drilling at that size, Spirit workers were directed to drill holes using a .2495 drill bit, to clear excess paint from the holes and speed up a slow process. Mr. Cuevas alleges that this caused the interference fit to be compromised in Row 3 of these fasteners, which houses critical electrical components, risking power failure and depressurization inflight. Mr. Cuevas observed that Boeing conducted an unannounced inspection and identified 117 out of 200 improperly drilled holes on the bulkhead, but that it has yet to correct the issue. Mr. Cuevas witnessed these problems with three planes he worked on and believes that these issues may affect at least 10-12 planes either in production or already released to Boeing.

Mr. Cuevas also alleges that, because of the ethics investigation, Spirit had fallen behind schedule on its repairs, and therefore instructed workers to incorrectly apply sealants to the plane's bulkhead fasteners. Usually, the first layer of sealant on this section of the plane requires approximately 168 hours to cure. On occasion, Mr. Cuevas witnessed only a two-hour gap between applying the first and second layer of sealant, which caused bubbles to form between the two layers, disrupting the needed torque to keep the fasteners in place. Boeing noticed this issue during its inspections on one aircraft and asked Spirit to reapply the sealants. Mr. Cuevas, however, fears that this and other issues, like the lack of an interference fit due to improper drilling, will go undetected on other planes.

Responding to the complaint, Boeing told the local paper Seattle Times that Cuevas' concerns were investigated and that an engineering analysis "determined the issues raised did not present a safety concern and were addressed."

"We are reviewing the documents released today and will thoroughly investigate any new claim," Boeing said.

Boeing's list of problems appears to be growing weekly (from federal investigations to hearings on Capitol Hill to whistleblowers to mid-air mishaps). One of the last whistleblowers (still living), Sam Salehpour, a former Boeing engineer, warned lawmakers on Capitol Hill in mid-April about safety concerns for the 787 and 777 aircraft.

Salehpour warned that the 787 Dreamliner fuselage was improperly put together and that the company "rushed to address the bottlenecks in production." The result, he warned, is "premature fatigue failure" on these planes. He noted, "They are putting out defective airplanes."

Meanwhile, outgoing Boeing's CEO Dave Calhoun apologized for the planemaker's recent series of safety failures in testimony delivered to a Senate committee last week.

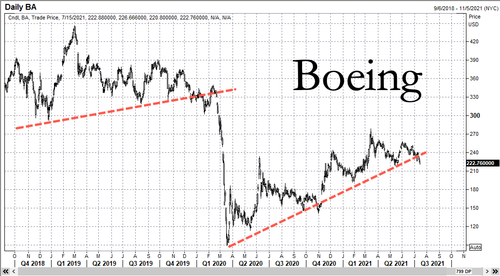

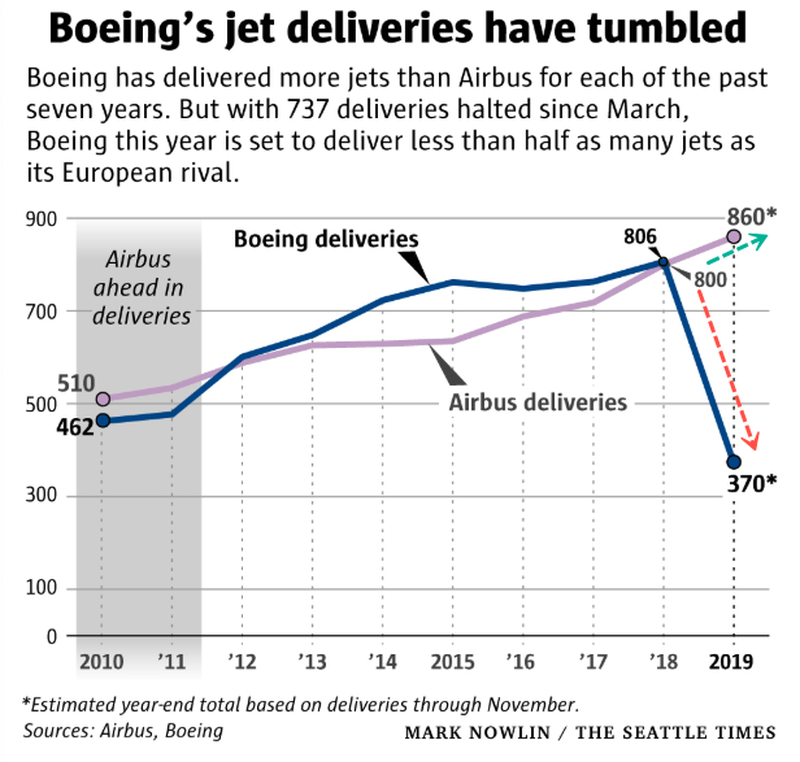

In markets, Boeing shares have been more than halved since peaking in early 2019 at $446 a share, which was around the time of the twin Max 737 crashes, killing 346 people.

From Zero Hedge

As Alaska Airlines and United Airlines have resumed flying Boeing 737 Max 9 jetliners in recent days, a new report from The Wall Street Journal finds that the incident involving a door plug being blown off an Alaska Airlines flight over Portland earlier in the month was probably caused by the lack of bolts. This issue dates back to when the aircraft was manufactured.

According to people familiar with the matter, what's becoming apparent is that the most likely scenario is that Boeing employees failed to reinstall plug door bolts at the factory after opening or removing them during production.

They pointed to the absence of markings on the door plug that would instruct factory workers to double-check if the bolts were in place and lapses in paperwork surrounding the factory's work on the doors.

When Spirit AeroSystems delivers the 737 fuselage to Boeing's Renton, Wash., factory for final assembly, the door plugs are installed. During the assembly process, the door plugs are removed and reinstalled.

Boeing has yet to reveal how many factory workers handled the door plug. It's important to note that Spirit's factory in Malaysia makes the door.

Last week, Sen. Tammy Duckworth (D., Ill.), chair of a Senate panel on aviation safety, met with Boeing Chief Executive David Calhoun about door plug woes.

"It is going to show that there has been lack of documentation when it comes with how and when those pins were installed or removed and whether or not they were reinstalled or not," said Duckworth.

She continued: "He assured me that they were going through that entire process to make sure that they are able to track on their aircraft when these things are happening."

Meanwhile, the Federal Aviation Administration has slapped Boeing with production limits on the jets amid an investigation into the door plugs.

From The Daily Reckoning

James Rickards

What happened to Boeing, the former gold standard of American industry? Nothing good, as I’ll show you today.

Simply put, Boeing isn’t the company it used to be.

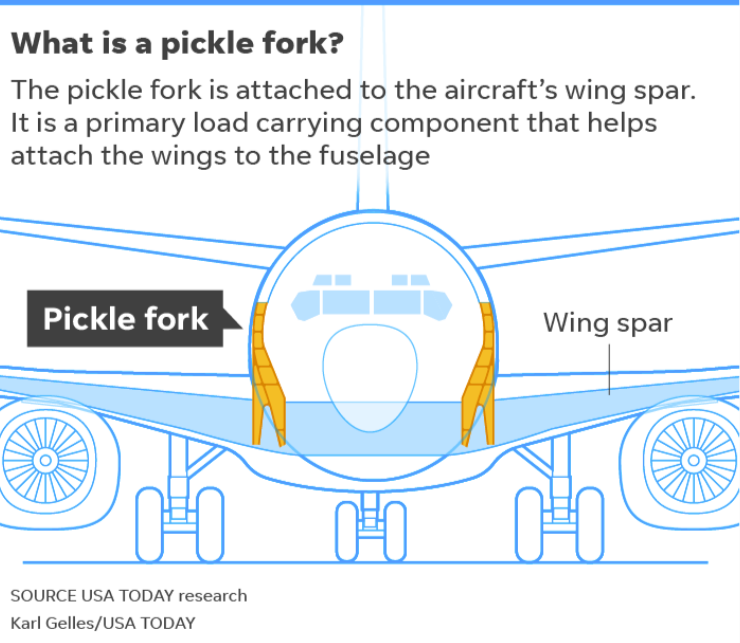

By now, I’m sure you’ve heard about the Jan. 6 near crash of a Boeing 737 Max 9 operated by Alaska Airlines, after the fuselage door blew off the plane. That caused decompression and the use of emergency oxygen.

The door blew out because of a door-plug failure at about 16,000 feet. At that altitude, temperatures are freezing, and oxygen is quite low relative to sea level.

The oxygen masks deployed, and passengers were able to secure them and hope for the best as the pilots tried to land the plane safely.

An altitude of 16,000 feet is practically the highest altitude that the passengers and crew could have survived the ordeal. At altitudes of 20,000 or higher, the depressurization would have caused extreme instability and possibly crashed the plane.

It’s also likely that passengers and crew would have passed out before being able to secure the oxygen masks. At 30,000 feet, just slightly higher than the summit of Mount Everest, the plane certainly would have crashed.

Fortunately, the plane landed safely with only minor injuries despite badly shaken nerves.

The fuselage door detaching was not the only disaster that occurred in those frightening minutes. The depressurization also caused the cockpit door to blow open, which exposed the pilots to the extreme wind and noise going on in the back of the plane at a time when they were desperately trying to stage an emergency landing.

Cockpit doors have been required to be highly secure and open from inside the cockpit only since the 9/11 hijackings. This was an added shock to the pilots at a critical time.

Boeing later lamely explained that the cockpit door is supposed to blow open during an extreme depressurization incident. But they never put that critical detail in the operating manual, and the pilots on the Alaska Airlines flight had no idea that would happen. Neither did many experts and engineers who were consulted by the media.

This separate critical incident will only add to the scrutiny, liability and criticism that Boeing is now experiencing for what is seen as gross incompetence.

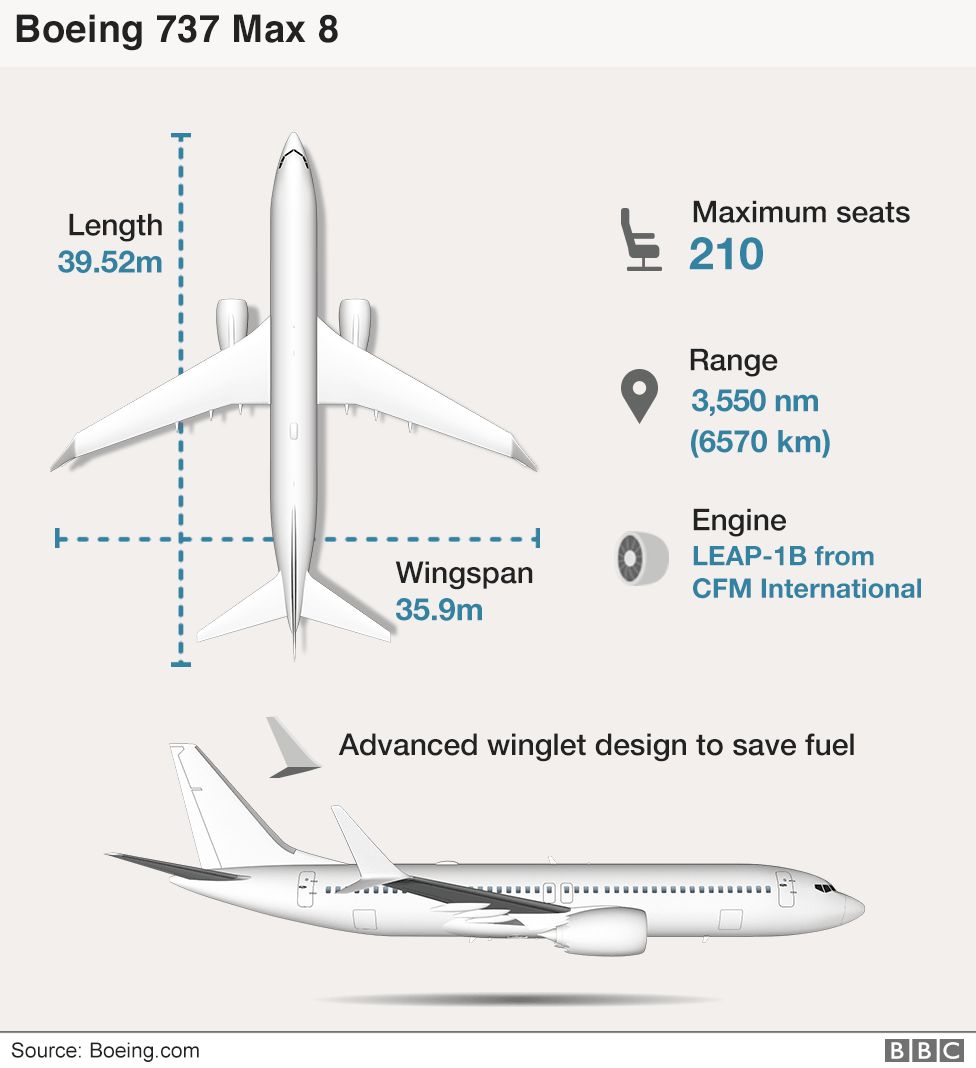

The double-door blowouts on the 737 Max 9 were bad enough. Of course, this comes not long after the double crashes of Boeing 737 Max 8 planes in Indonesia in October 2018 and Ethiopia in March 2019. These were due to software flaws that put the planes into dives that pilots hadn’t been trained to counter.

Boeing’s global fleet of 737 Max 8 planes were grounded at that time. However, Boeing was seen as slow to respond after the first crash. It was really the airlines themselves that took the lead in grounding their own planes.

Boeing vowed internal investigations and improvements in quality control at that time. The flaws were subsequently corrected, but obviously problems remain. Here we are just five years later with another quality control fiasco grounding another fleet of aircraft.

The plane involved in the latest incident was basically brand-new. It wasn’t an older aircraft that experienced metal fatigue.

According to news reports, both Boeing and Alaska Airlines had some indications that there were difficulties with the door plugs on the fuselage door.

Since the 737 Max 9 is a relatively new model and the particular plane that suffered the door failure was, again, almost brand-new, engineers decided to ignore the warnings as just a kink that sometimes appears in new equipment and will self-correct or be easily adjusted.

This was not the case; the manufacturer and operator were both receiving warnings of a potential catastrophic failure that they chose to ignore.

Boeing has now grounded its entire global fleet of 737 Max 9s, about 170 aircraft in all.

Where did it all start going wrong for Boeing? You can trace the answer to its 1997 merger with rival aircraft manufacturer McDonnell Douglas. That changed Boeing’s culture, and for the worse.

Boeing was known for its strong emphasis on engineering and quality control. It was part of the company’s ethos.

McDonnell Douglas, on the other hand, placed special emphasis on cost cutting and financial innovations to improve its bottom line. It’s not that it completely neglected quality control or that it didn’t care about safety. Obviously, airplane manufacturers can’t afford to disregard them.

It’s just that it placed relatively greater emphasis on financial considerations than Boeing.

But after the merger, the McDonnell Douglas model began to encroach on Boeing’s traditional ethos. The engineering department was greatly reduced, for example, while the financial engineers went to work.

Starting in 2010, Boeing spent tens of billions on stock buybacks and other financial machinations to enhance its share price. At the same time, the company took on massive amounts of debt.

Boeing’s new CEO, Harry Stonecipher, even cited all this as a feature, not a bug. He was proud of it.

He said, “When people say I changed the culture of Boeing, that was the intent — so run like a business rather than a great engineering firm.”

What was the result? Safety issues that resulted in two crashes and the latest close call. As one Boeing engineer who worked on the 737 Max said in 2019:

This program was a much more intense pressure cooker than I’ve ever been in. The company was trying to avoid costs and trying to contain the level of change. They wanted the minimum change to simplify the training differences, minimum change to reduce costs and to get it done quickly.

The irony is that by attempting to cut costs, Boeing has suffered great costs.

Legal liability will be enormous. Business losses will also be huge based on grounding the entire fleet, identifying the defects and repairing them on all of the existing planes as well as making assembly adjustments to any work in progress.

New safety protocols will have to be developed to make sure the problem does not reoccur, and pilots, crews and ground personnel will have to be retrained to look for future problems. The airlines will suffer losses from the groundings and will seek recourse from Boeing.

Boeing stock has fallen from $265 per share on Dec. 15 to $227 per share today (about a 15% decline in three weeks).

Has Boeing’s stock already taken its hit on this fiasco? The answer is no. The market price has adjusted somewhat but the investigations are ongoing, and the costs of responding are being grossly underestimated.

Markets can be partly efficient but are not highly efficient and sometimes get taken in by “all clear” narratives put out by Wall Street that are far from the truth.

This story has much longer to run, more negative facts will emerge, management changes are likely and the stock has much further to fall.

From Yahoo News

Boeing 737 Max 9 problems mount following Alaska and United Airlines incidents.

By Kate Murphy

On Monday, United Airlines said loose bolts and other "installation issues" were discovered on the door plugs of some of its fleet of Boeing 737 MAX 9 airplanes.

“Since we began preliminary inspections on Saturday, we have found instances that appear to relate to installation issues in the door plug – for example, bolts that needed additional tightening,” United said.

The mandated inspections come after the Federal Aviation Administration forced the grounding of Boeing 737 MAX 9 airplanes. Alaska Airlines and United are the only two U.S. airlines that use that particular model of the Boeing 737.

“Boeing 737-9 aircraft will remain grounded until operators complete enhanced inspections, which include both left and right cabin door exit plugs, door components, and fasteners,” the FAA said in a statement on Monday, adding that any issues found from the inspections must be corrected before the planes can go back into service.

The pause, which resulted in the cancellation of hundreds of flights, affected about 171 planes globally, according to the Federal Aviation Administration.

On Friday, Alaska Airlines Flight 1282 had to make an emergency landing shortly after takeoff after a door plug blew out, leaving a large hole in the side of the plane as it climbed. The door plug has since been recovered and the National Transportation Safety Board launched an investigation over the weekend into what it called “an accident.”

Boeing’s shares tumbled as much as 9% as trading opened on Monday morning, the first business day since the incident.

Incredibly, none of the 171 passengers and six crew members on board the flight from Portland, Ore., to Ontario, Calif., was injured.

The plane was climbing at about 16,000 feet when a panel on the plane’s fuselage was blown out.

No one was seated in 26A and 26B, where the door plug was located.

“We are very, very fortunate here that this didn’t end up in something more tragic.” NTSB Chair Jennifer Homendy said over the weekend.

The airplane had not reached cruising altitude and the seat belt sign remained on to discourage passengers and crew members from walking around the cabin.

“Just from talking with everyone who was part of the interviews, it was described as chaos, very loud, between the air and everything going on around them,” Homendy said at a Sunday news conference. “And it was very violent when the rapid decompression and the door [plug] was expelled out of the plane.”

Some passengers were treated for minor injuries on board.

The lost door plug — which weighs 63 pounds and is 26 inches x 48 inches — was found on Sunday in the backyard of a Portland school teacher.

NTSB investigators will examine the plug to search for evidence about how it became dislodged and will compare it with the plane’s door plug on the other side.

The plane used for Flight 1282 had other issues. After a warning light signaling a pressurization issue went off during three previous flights, the plane had been restricted from longer routes to Hawaii that travel over open water. That restriction was put in place in the event the warning light reappeared so as to enable the plane to quickly return to an airport. The warning light had previously gone off on Dec. 7, 2023, and Jan. 3 and Jan. 4, just one day before the door plug flew off.

Alaska Airlines had ordered additional maintenance personnel to look at the pressurization warning light, Homendy added, but it wasn’t completed before Friday’s accident. Homendy acknowledged that the warning light issue may be unrelated.

An additional hurdle is that the investigators will not be able to rely on Flight 1282’s cockpit data recorder.

“The cockpit voice recorder was completely overwritten ... at two hours it re-records over it so we have nothing from the CVR [cockpit voice recorder],” Homendy told reporters, adding that it is “critical” to increase that recording time to 25 hours, the standard Europe and many other countries currently have in place.

While the Federal Aviation Administration has proposed a new rule to put that increase in place, it would only apply to newer flights. So the Alaska Airlines flight would not have qualified, Homendy said.

Two cellphones that appeared to belong to passengers aboard Flight 1282 were later recovered. One was found in a yard, and the other on the side of a road.

In its investigation, the NTSB is expected to work with officials from Alaska Airlines, Boeing, the FAA and groups representing pilots and flight attendants.

“While we await the airworthiness directive inspection criteria from the FAA and Boeing, our maintenance teams are prepared and ready to perform the required inspections,” Alaska Airlines said in a statement. The airline said that cancellations will continue for the first half of the week and that passengers should check alaskaair.com for updates.

United Airlines also issued a statement on X and said they are working with customers affected to find them “alternative travel options” and advised them to check for updates at united.com or on the United app for the latest.

Meanwhile, Boeing CEO Dave Calhoun sent a companywide memo saying, in part, “When serious accidents like this occur, it is critical for us to work transparently with our customers and regulators to understand and address the causes of the event, and to ensure they don’t happen again. This is and must be the focus of our team right now.”

Calhoun plans to hold an all-employee safety meeting on Tuesday at the 737 factory in Renton, Wash.

From Zero Hedge

Fake Jet Engine Parts Supplied To Repair Shops For Older Airbus And Boeing Planes

By Tyler Durden

European aviation authorities have flagged a London-based firm for supplying "unapproved parts" for jet engines on older Airbus SE A320s and Boeing Co. 737s.

"Numerous Authorised Release Certificates for parts supplied via AOG Technics have been forged," the European Union Aviation Safety Agency wrote in a statement to Bloomberg.

London-based AOG Technics sold CFM56 jet engine parts to third-party repair shops servicing older A320s and 737s. EASA said the parts had certificates the manufacturer could not authenticate or confirm "they were not the originator of the part."

"Manufacturers and regulators sounded the alarm weeks ago, triggering a global scramble to trace parts supplied by AOG Technics and identify affected aircraft," Bloomberg said.

EASA said the parts with "falsified Authorized Release Certificate" were for CFM56 engines installed on older narrow-body planes. The regulator has told airlines to quarantine parts that potentially could have fake documentation.

"The documentation of parts is a very critical issue," said Klaus Mueller, a senior adviser at AeroDynamic Advisory and a former senior executive at MTU Aero Engines AG and Deutsche Lufthansa AG's maintenance arm.

Mueller said, "The industry is taking this topic very, very seriously."

This development is a significant headache for European airlines because how many parts with fake documentation AOG Technics flooded airlines with is still being determined.

Bloomberg said CFM International, the GE-Safran manufacturing venture of the engine, has alerted customers and shops about the fake certification documents and unapproved parts for the CFM56s.

EASA said if a part has falsified documentation, "then it is recommended that the part be replaced with an approved part."

Yet more headaches for airlines operating older A320s and 737s because finding fake parts on their aircraft will take time. It also comes as aircraft parts are in short supply.

Hundreds of US Airline Pilots Suspected of Being Unfit to Fly

MOSCOW (Sputnik) - About 600 US pilots licensed to operate passenger flights are under investigation for lying about their medical records, US press reported Sunday, citing officials and internal records.

The Federal Aviation Administration (FAA) has been looking into 4,800 former military veterans turned airline and commercial pilots who might have submitted "incorrect or false information" as part of their medical applications, FAA spokesman Matthew Lehner admitted in a comment to the daily.

The pilots were red-flagged after investigators at the Department of Veterans Affairs cross-checked federal databases to discover aviators who were receiving veteran benefits for mental health disorders and other serious conditions, while hiding their true medical history from the FAA in order to continue flying.

While the FAA relies on screening to identify safety risks, the tests are often cursory and pilots are expected to self-report conditions that can otherwise be difficult to detect, such as depression or post-traumatic stress, The Washington Post cited physicians who conduct the exams as saying.

Officials told the newspaper they suspected many of the pilots under investigation of being either too sick to fly or defrauding taxpayers by exaggerating their disabilities to claim bigger benefits. The FAA disbursed $3.6 million starting last year to run additional tests on thousands of pilots deemed "potential risks."

From Zero Hedge

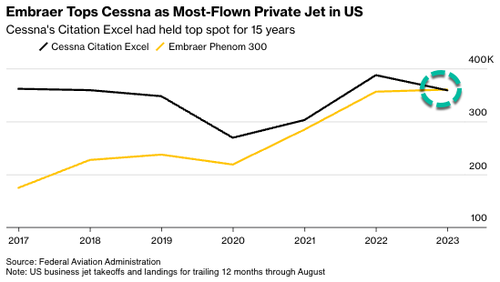

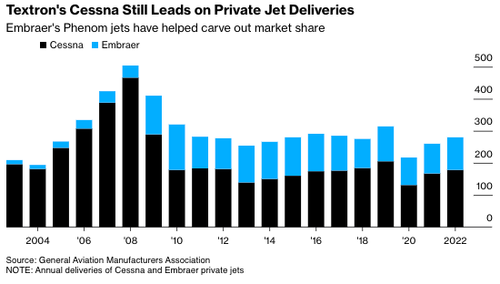

The Most Flown Private Jet In The US Is...

By Tyler Durden

In a rapid shift in private aviation among millionaires, cent-millionaires, and billionaires, Textron Inc.'s Cessna Citation, the most popular and most flown private jet in the US, which held that record for 15 years, has just been dethroned.

Bloomberg reports new monthly flight data from the Federal Aviation Administration shows Brazil's Embraer Phenom 300, a medium-sized jet that seats around nine passengers, had 360,000 takeoffs and landings at US airports in the 12 months through August, 1,200 more than the Citation Excel family of jets.

Brian Foley, a private aviation consultant, said the biggest reason behind the surge in popularity of the Phenom 300 is fuel efficiency, which burns one-third less than the Citation Excel. He said cheaper fuel costs offset the Phenom 300's smaller cabin space.

For some context, at cruising speed, the two Pratt & Whitney turbofans of the Citation Excel burn around 225 gallons per hour of Jet A fuel.

Meanwhile, the Phenom 300 is around 158 gallons of Jet A fuel per hour.

Even though Phenom 300s are being flown more, Cessna still dominates private jet deliveries.

Textron told Bloomberg, "One of every three business jets worldwide is a Cessna Citation, and product upgrades like these continue to give customers new reasons to choose us for our proven performance, leading technology and unmatched cabin experience."

Despite the 'climate change' cheerleading, private jet demand soared to new heights in recent years, though mounting macro uncertainty and the highest interest rates in two decades led to a cooling in private jet flights earlier this year.

From Statista

The World’s Ten Busiest Airports - By Anna Fleck

Hartsfield-Jackson Atlanta International Airport, U.S., was the world's busiest airport in 2022, with an annual footfall of some 93.7 million passengers. The figure is 24 percent higher than in 2021, but 15 percent lower than in 2019, the year before the pandemic. It is followed by Dallas-Fort Worth Airport, with 73.4 million travelers, and Denver Airport, with 69.3 million, according to data released by Airports Council International (ACI).

After 22 years leading the charge as the number one airport for passenger volume, Atlanta's airport was pushed to second place in 2020 by Canton Baiyun International Airport, China. However, the Chinese airport fell to eighth place a year later and the U.S. airport once again topped the list.

As the following infographic shows, five of the top ten airports with the highest passenger traffic last year were in the United States. ACI highlights that all ten, representing 10 percent of global traffic, have a significant share of domestic traffic - the segment that has led the global recovery.

The total number of passengers worldwide in 2022 was estimated to hit nearly 7 billion, representing an increase of nearly 54 percent over 2021.

From Zero Hedge

Air travel demand soared back to pre-Covid times during the Fourth of July holiday weekend. But with rising demand for air travel comes persistent flight delays and cancellations due to a pilot shortage. Some of the reasons for a pilot shortage have been a surge in early retirements during the pandemic, a mandatory retirement age of 65, a shrinking pool of potential pilots from the military, and a challenging value proposition for civilians to pursue a career as a pilot.

We have told readers there's "no quick fix" to the severe pilot shortage. Airlines like American Airlines have seen flight disruptions this summer due to a lack of pilots.

Current figures from the Federal Aviation Administration show the aviation industry is short 32,000 commercial pilots, mechanics, and air traffic controllers -- and the gap continues to expand by the year.

Transportation Secretary Pete Buttigieg told CBS News his office is investigating several airlines that book "unrealistic" scheduling by selling seats ahead of scheduling personnel to fly planes.

"If you look at the delays, for example, that America experienced through last year in the summer 2022, a lot of that was driven by these companies not having the staff that they needed," Buttigieg said.

"This is not something that's going to be worked out overnight. It took years to get this way," he warned.

Wichita State University emeritus associate professor Dean Headley said, "The pilot shortage won't be resolved until 2032 or something like that."

Headley said airlines can train 1,500 to 1,800 pilots a year but noted with a deficit of 17,000 pilots, "we can't catch up that quick."

The current pilot shortage has forced commercial airlines to "cut back flights to smaller regional airports. So, people [who] are not at a major airport will find that their flight schedules have been reduced simply because they don't have enough people to put in an airplane to fly it somewhere," Headley explained

Besides a pilot shortage, the Office of Inspector General for the Department of Transportation revealed in early July there was also a severe shortage of air-traffic controllers. And just like pilots, it takes years to train air-traffic controllers.

One airline lobbying group has asked Congress to allow just one pilot in the cockpit to alleviate the shortage.

The shortages in pilots and air-traffic controllers won't be resolved anytime soon. No longer can airlines blame the "weather."

From FlightGlobal

US House committee approves bill to hike pilot retirement age to 67

By Jon Hemmerdinger

A US lawmaking committee has approved a measure that would increase the USA’s mandatory airline-pilot retirement age, spurring criticism from pilot unions and earning praise from regional airlines.

The US House of Representatives’ transportation committee on 14 June approved the change, which would bump up the mandated retirement age of airline pilots in the USA from 65 to 67, according to reports.

Whether the measure, which passed by a narrow margin, will ultimately become law remains unclear.

It is part of a broader House bill to fund the Federal Aviation Administration after the agency’s current funding expires in October. The full US House is expected to vote on that broader bill in July, the committee says.

Meanwhile, a US Senate committee is expected today to vote on its own version of the funding bill. The chambers must then negotiate to finalise a single law.

But increasing the retirement age has strong support from the Regional Airline Association, a group whose members say they have been particularly hurt by an industry-wide pilot shortage.

A two-year bump in the required retirement age “will have an immediate, positive effect for small community air service”, the RAA says.

“Raising the pilot retirement age is the one solution that will have a near-immediate effect on the pilot shortage, allowing time for more long-term solutions to mature,” says the RAA. “It’s also the right thing to do for pilots who are today being pushed out of flight decks while they still have much to offer.”

US regional airlines have said too few pilots have forced them to ground hundreds of regional aircraft and cut air service to smaller communities. In the USA, airlines have about 490 regional jets (including Bombardier CRJs and Embraer E-Jets) in storage, and 1,340 in service, according to Cirium fleets data.

Airlines for America, the trade group representing large US airlines, declines to comment.

But US pilot unions are raising alarm. The unions have also denied the existence of a pilot shortage, saying airline mismanagement and low pay are keeping carriers from filling their ranks.

In a 14 June letter to lawmakers, Air Line Pilots Association (ALPA) president Jason Ambrosi calls the retirement-age change “anti-union” and “politically driven”. ALPA says the measure will worsen a pilot-training backlog, put the USA out of step with international standards and erode aviation safety.

“There is an increased risk of cardiovascular issues, diabetes and cognitive decline with increasing age. It is imprudent for Congress to impose its own view on safety,” Ambrosi says.

The union, which represents pilots at numerous airlines, notes that existing ICAO standards call for retirements at age 65.

It says US pilots older than 65 years would be unable to fly some international flights, which are typically operated by widebody aircraft. As a result, such pilots would likely need to be retrained to fly narrowbody jets, which would “displace junior pilots” and create “a cascading training backlog”.

The Allied Pilot Association (APA), which represents pilots at American Airlines, likewise opposes increasing the required pilot retirement age.

“Safety considerations drove the establishment of the current international standard of age 65 mandatory retirement, and raising the pilot retirement age would introduce additional risk into commercial aviation,” says APA president Ed Sicher.

From Bloomberg

By Danny Lee

China Jet to Rival Airbus, Boeing Makes First Commercial Flight

A made-in-China aircraft to rival Boeing Co. and Airbus SE underwent its maiden commercial flight on Sunday, almost six months after being delivered to China Eastern Airlines Corp.

Flight MU9191 took off from Shanghai at 10:32 a.m. local time, China Eastern said on its Weibo account. The plane carried 128 passengers and landed safely at Beijing, People’s Daily said in a tweet.

The commercial debut marks a long journey for Commercial Aircraft Corp of China Ltd., or Comac as it is better known. The manufacturer first starting developing the narrow-body airliner in 2008 and production began in late 2011. But it wasn’t until September 2022 when the C919 received official certification to fly, marking the long end of flight testing and paving the way for Comac to start deliveries.

Read more: China Delivers First Homegrown Plane to Take On Boeing, Airbus

China Eastern is the C919’s launch customer, with an order for five. After the first jet’s delivery in December, the aircraft undertook a period of flight activities almost daily in order to satisfy a requirement for 100 hours of proving flights. But from Feb. 7 to May 17, China Eastern’s C919 hadn’t flown regularly for 104 days, FlightRadar24 data show.

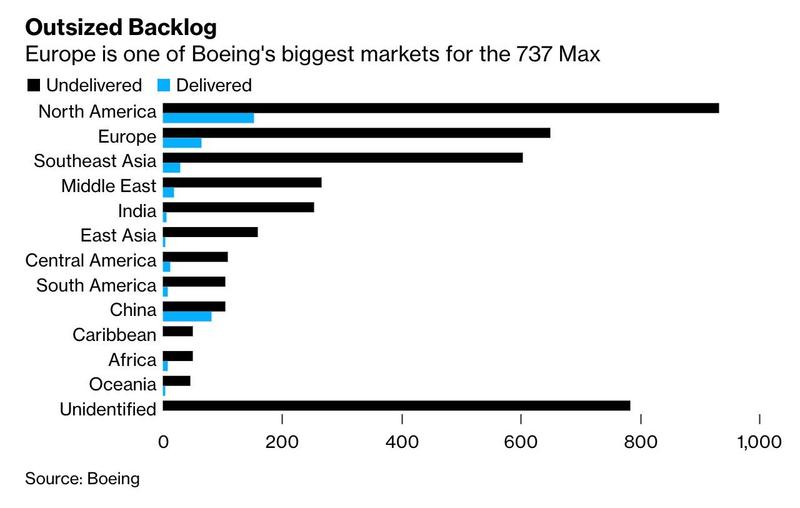

China is angling to disrupt the dominance of Boeing and Airbus in commercial jetliner manufacturing. Both Airbus’s A320neo family and Boeing’s 737 Max jets have a full order book through to the end of the decade, meaning any carrier wanting narrow-body jets sooner may need to find an alternative.

Read more: China’s Rival Aircraft to Boeing, Airbus Jets Wins Certification

Comac has garnered more than 1,000 orders for the C919, though the majority aren’t confirmed and many are from Chinese aircraft lessors yet to place the jet with an airline.

Doubts remain over Comac’s ability to fulfill those orders. The Chinese manufacturer is also reliant upon foreign suppliers including General Electric Co., Honeywell International Inc. and, for the engines, CFM International Inc. — a venture between GE and France’s Safran SA.

Shanghai-based China Eastern, one of the country’s biggest carriers, said on its earnings call last week that it plans to bring all five C919s into its fleet in 2023.

The C919 remains certified only to fly within China, however, while European certification remains ongoing. Each C919 costs around $99 million, before customary discounts to airlines.

From Mark

This weekend..... if all goes well, Rotate.Aero will be upgrading to Joomla 4.

Joomla is a CMS or Content Management System that is similar to Word Press.

Both have site interaction which utilizes databases for storage.

Upgrading to Joomla 4 will be quite a task, so for the next couple of days, no Forum or Blog entries will be made.

Thanks

From Zero Hedge

By Tyler Durden

The Federal Aviation Administration (FAA) is assembling a team of experts to review a series of near-miss incidents and mishaps that could have sparked air disasters.

On Tuesday, FAA Administrator Billy Nolen penned a "call to action" memo that specified a team of safety experts will "examine the US aerospace system's structure, culture, processes, systems, and integration of safety efforts."

"We are experiencing the safest period in aviation history, but we cannot take this for granted," Nolen wrote. He added, "Recent events remind us that we must not become complacent."

His memo comes after a series of alarming incidents, including a United Airlines Boeing 777-200 that came within 800 feet of impacting the Pacific Ocean off Maui on Dec. 18, a computer 'glitch' that grounded all US flights on Jan. 11, a FedEx cargo jet that almost landed on a Southwest Airlines commercial plane at Austin-Bergstrom International Airport in Texas on Feb. 4, and a close call at York's John F. Kennedy International Airport on Jan. 16 when American Airlines plane crossed a runway when a Delta Air Lines flight was taking off.

Link to full memo: https://cms.zerohedge.com/s3/files/inline-images/faa_0.jpg?itok=PvXgRP6c

All this is happening as passengers had just overcome their fear of flying on Boeing 737 Max planes. These near misses and computer problems are very concerning.

The US has not had a major fatal air disaster since February 2009.

Pilots are dying at Southwest Airlines at over 6X the normal rate after the COVID vaccines rolled out.

And disabilities are up 10X normal. I thought the vaccines were supposed to reduce death not increase it! I just asked the FAA for their comment, but no answer.

Please read more at link below:

https://stevekirsch.substack.com/p/pilots-are-dying-at-southwest-airlines

By Steve Kirsch

Long and informed article which is linked here. Please take the time to read it.

From Zero Hedge

Airlines, in their infinite mission to balance costs, profits, and keeping planes full of passengers alive between two points, might be going a little too far in their latest attempt to cut back.

According to CBS News, the industry has been quietly lobbing Congress to allow them to use just one pilot in the cockpit instead of two, as is currently required by part 121 of the Federal Aviation Regulations.

The airlines claim it would quickly solve staffing issues caused by the ongoing pilot shortage, and say that technology has improved to the point where it would be perfectly safe to do so.

There's language in a new bill now introduced in Congress — the Federal Aviation Administration reauthorization bill — asking the Federal Aviation Administration to reconsider part 121 and to allow the use of a single pilot operation, first in cargo aircraft.

Not surprisingly, airline pilots are loudly protesting this idea, claiming that it would diminish a safety discipline and culture that has been responsible for the safest 25 years in commercial aviation in the history of aviation. Pilots unions argue it's all about the airlines saving money and could compromise safety. -CBS News

Unions have pointed to several examples of emergency situations in which two pilots were necessary - such as the "Miracle on the Hudson," when pilots Chesley "Sully" Sullenberger and Jeffrey Skiles worked together to glide a US Airways flight down to New York's Hudson river after it hit a flock of Canadian geese on takeoff, saving all 150 passengers and crew.

Meanwhile, 10 days ago an American Eagle flight from Chicago to Columbus had an emergency when one of the two pilots became incapacitated. The co-pilot was able to gain control of the plane, declare an emergency, and safely land back in O'Hare.

The pilot later died at the hospital.

From Airline Ratings

LAST 747 TO BE DELIVERED IN OCTOBER TO ATLAS AIR

By Geoffrey Thomas

The last Boeing 747 will be delivered in October to Atlas Air bringing the curtain down on the production of the world’s most iconic commercial jet.

The last 747, a -8F is the 1574th built of a production run that has spanned 55 years.

Atlas Air, the world’s largest operator of the 747 has 57 of the giant jets in both freighter (52) and passenger configurations (5).

It is just over 50 years since the 747 entered service with Pan American on a flight from New York to London.

But the first passenger service got off to a rocky start with engine problems and was delayed by six hours and a substitute 747 was used.

The birth of the 747 was also rocky and was to bring dark clouds to the leaders in commercial aviation at the time and almost bankrupted all three.

Ironically, the 747 wasn’t supposed to carry passengers for very many years as the world looked to supersonic travel with the Boeing SST and the Concorde.

Giving life to the aircraft that changed the world was a challenge that brought the world’s largest aerospace company, Boeing, the then biggest engine builder Pratt, and Whitney and the legendary Pan Am to their knees.....

Please visit Airline Ratings for the complete article.

From Aerotime.Aero

FedEx Asks FAA Permission To Add Missile-Defense System To A321 Freighter.

By Gabriele Petrauskaite

American cargo airline FedEx is seeking permission from the Federal Aviation Administration (FAA) to install a laser-based missile-defense system on its cargo aircraft.

In the filing dated January 7, 2022, the Department of Transportation of the Federal Aviation Administration confirmed that FedEx had asked permission to modify the Airbus A321-200 aircraft by installing the system.

In the document, the FAA stated that FedEx applied for a specific type certificate, which would allow the company to modify the commercial transport-category plane in October 2019. At the time, FedEx asked permission to install “a system that emits infrared laser energy outside the aircraft,” the FAA filing reads.

There have been a number of incidents in recent years where civilian planes have been targeted by man-portable air defense systems. As a result, laser-based missile defense systems began to be installed on aircraft in order to protect them against heat-seeking missiles.

However, the FAA shared safety concerns about the implementation of such a system.

“The FedEx missile-defense system directs infrared laser energy toward an incoming missile, to interrupt the missile’s tracking of the aircraft’s heat. Infrared laser energy can pose a hazard to persons on the aircraft, on the ground, and on other aircraft. The risk is heightened because infrared light is invisible to the human eye. Human exposure to infrared laser energy can result in eye and skin damage, and affect a flight crew’s ability to control the aircraft,” the American aviation body explained.

It continued: “Infrared laser energy also can affect other aircraft, whether airborne or on the ground, and property, such as fuel trucks and airport equipment, in a manner that adversely affects aviation safety.”

The FAA, which is the largest transportation agency in the US, also outlined that it could approve design features on the Airbus A321-200 jet and allow FedEx to install the modifications if the system is equipped with “means that prevent the inadvertent activation of the system on the ground”. The company will also need to ensure that the operating the system during the flight does not pose a risk to other aircraft or people.

In the meantime, the FAA is also required to place the laser system safety-related information at the location of the laser installation as well as to provide necessary instructions and warn over hazards associated with exposure to laser radiation.

“The airplane flight manual supplement (AFMS) must describe the intended functions of the installed laser systems, to include identifying the intended operations and phases of flight. The AFMS must state: CAUTION: The operation of the installed laser system could pose a significant risk of injury to others while in proximity to other aircraft, airports, and populated areas,” the FAA determined.

However, FedEx does not currently operate any Airbus A321-200 jets. The recent FAA filing could imply that the airline is planning to purchase aircraft of this type.

From The Associated Press

DALLAS (AP) — A former Boeing pilot was indicted Thursday by a federal grand jury on charges of deceiving safety regulators about the 737 Max jetliner, which was later involved in two deadly crashes.

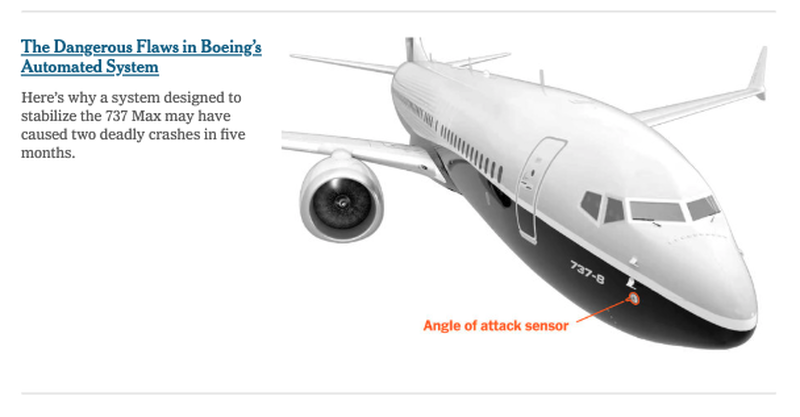

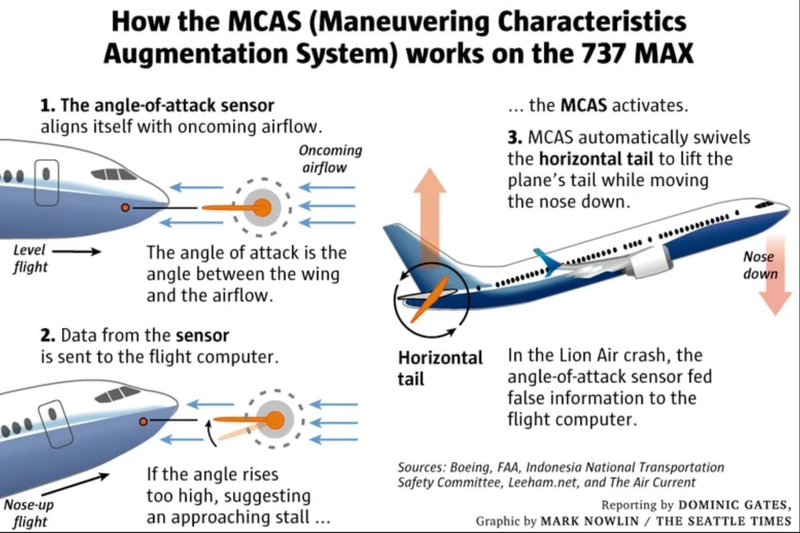

The indictment charges Mark A. Forkner with giving the Federal Aviation Administration false and incomplete information about an automated flight-control system that played a role in the crashes, which killed 346 people.

Prosecutors said that because of Forkner's alleged deception, the system was not mentioned in pilot manuals or training materials.

An attorney for Forkner did not immediately respond for comment. Boeing and the FAA declined to comment.

Forkner, 49, was charged with two counts of fraud involving aircraft parts in interstate commerce and four counts of wire fraud. Federal prosecutors said he is expected to make his first appearance in court on Friday in Fort Worth, Texas. If convicted on all counts, he could face a sentence of up to 100 years in prison.

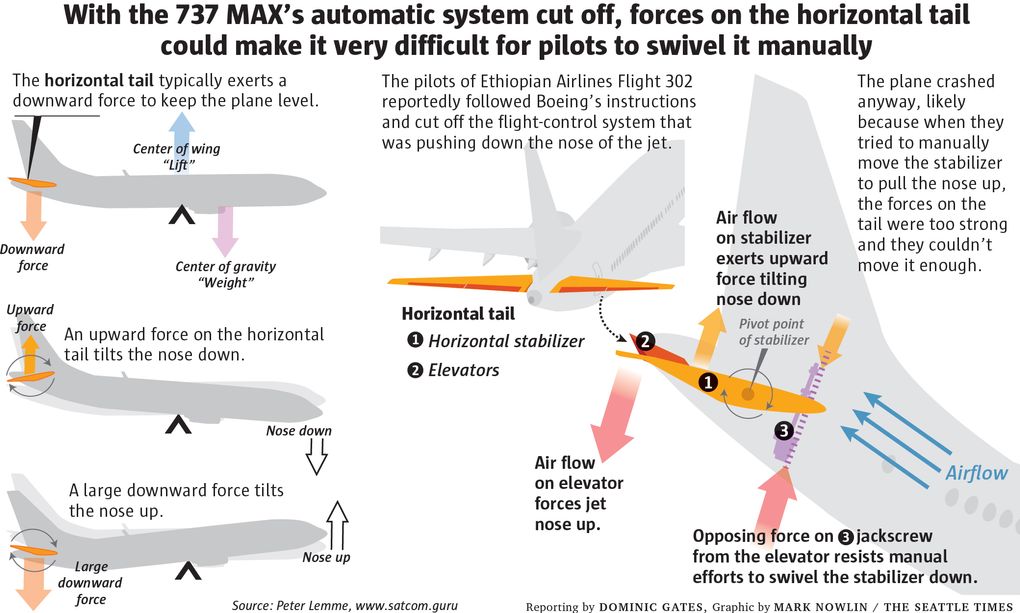

The indictment charges that he hid information about a flight-control system that activated erroneously and pushed down the noses of Max jets that crashed in 2018 in Indonesia, and 2019 in Ethiopia. The pilots tried unsuccessfully to regain control, but both planes went into nosedives minutes after taking off.

Forkner was Boeing's chief technical pilot on the Max program. Prosecutors said that Forkner learned about an important change to the Maneuvering Characteristics Augmentation System flight-control system in 2016, but withheld the information from the FAA. That led the agency to delete reference to MCAS from a technical report and, in turn, it didn’t appear in pilot manuals. Most pilots didn’t know about MCAS until after the first crash.

Prosecutors suggested that Forkner downplayed the power of the system to avoid a requirement that pilots undergo extensive and expensive retraining, which would increase training costs for airlines. Congressional investigators suggested additional training would have added $1 million to the price of each plane.

“In an attempt to save Boeing money, Forkner allegedly withheld critical information from regulators,” said Chad Meacham, acting U.S. attorney for the northern district of Texas. “His callous choice to mislead the FAA hampered the agency’s ability to protect the flying public and left pilots in the lurch, lacking information about certain 737 MAX flight controls."

Forkner told another Boeing employee in 2016 that MCAS was “egregious” and “running rampant” when he tested it in a flight simulator, but he didn't tell that to the FAA.

“So I basically lied to the regulators (unknowingly),” Forkner wrote in a message that became public in 2019.

Forkner, who lives in a Fort Worth suburb, joined Southwest Airlines after leaving Boeing, but left the airline about a year ago.

Chicago-based Boeing agreed to a $2.5 billion settlement to end a Justice Department investigation into the company's actions. The government agreed to drop a criminal charge of conspiracy against Boeing after three years if the company carries out terms of the January 2020 settlement. The settlement included a $243.6 million fine, nearly $1.8 billion for airlines that bought the plane and $500 million for a fund to compensate families of the passengers who were killed.

Dozens of families of passengers are suing Boeing in federal court in Chicago.

Crash investigations highlighted the role of MCAS but also pointed to mistakes by the airlines and pilots. Max jets were grounded worldwide for more than a year and a half. The FAA approved the plane for flying again late last year after Boeing made changes to MCAS.

From Zero Hedge

By Tyler Durden

The FAA isn't done punishing Boeing for the oversights (later revealed to be systemic) that led to the devastating crashes of two Boeing 737 MAX 8 jets, killing roughly 350 passengers and crew.

According to a WSJ report, the FAA is launching a "broad review of how Boeing employees handle safety matters" after several company engineers told the agency they had faced "undue pressure" to skirt over them.

The FAA survey, conducted this year, revealed that 35% of a small sample of certain Boeing employees reported problems including pressure and hurdles to transparency, according to an Aug. 19 agency letter to Boeing that was obtained by WSJ. Some surveyed employees, who are part of a group empowered by the agency to assist with its work, said they encountered difficulties in being transparent with regulators.

As WSJ explained, aviation regulators have long relied on engineers to act on the agency's behalf when performing certain tasks, especially when it comes to signing off on safety assessments. Any lapses in Boeing's safety overviews should have been anonymously reported to the agency. Yet, as we learned more than 18 months ago, engineers working on the 737 MAX 8 resented their managers, and privately complained to one another about the shortcomings of their oversight - without ever saying a word to the FAA.

According to the letter seen by WSJ, the survey indicated that some 35% of the small sample of Boeing employees surveyed complained to the agency that their work environment "does not support independence" of those who are empowered to act on the agency’s behalf, according to the letter, which was signed by Ian Won, acting manager of the FAA’s Boeing oversight office in the Seattle area.

In the aftermath of the 737 MAX 8 crashes (which famously led to the plane being grounded for more than a year) WSJ's reporting revealed that the FAA had effectively let Boeing regulate itself following an unprecedented incidence of "regulatory capture."

Yet, now we're learning that the "problems cited by Boeing employees in the survey 'indicate the environment does not support independence' of those who are empowered to act on the agency’s behalf, according to the letter, which was signed by Ian Won, acting manager of the FAA’s Boeing oversight office in the Seattle area."

In the survey, the employees complained about pressure that sometimes came from management, and sometimes came from fellow engineers.

The two-page letter came with excerpts from interviews with Boeing employees. The employees, who were quoted anonymously, told the FAA that the pressure they felt wasn’t necessarily overt and could also come from the engineering ranks pushing to stay on schedule.

"I feel undue pressure but I stand up to it," one Boeing employee was quoted by the letter as saying.

The FAA letter said that "Boeing’s company culture appears to hamper" its FAA-empowered employees "from communicating openly with the FAA." The letter cited one Boeing employee who told the agency: "I am very aware that my bringing up issues is not appreciated."

A Boeing spokesperson said the company "takes these matters with the utmost seriousness" and is working to bolster the independence of its employees who work on the FAA's behalf.

"We have consistently reinforced with our team that delegated authority is a privilege and that we must work every day to be trusted with the responsibility," she said. Boeing has directed that its FAA delegates "must be accorded the same respect and deference that is shown to our regulator."

Unfortunately, the problems cited by the August letter are all too familiar: they're the same issues that were identified by an internal company report that was obtained by Congress during its investigation into the two deadly crashes, which took place in October 2018 and March 2019.

From The Seattle Times

By Charlotte Ryan

Bloomberg

Airbus said its decades-old competition with Boeing is back on in earnest as the removal of coronavirus curbs revives international travel and unleashes a spate of jetliner order contests.

The European firm said Thursday that the traditionally fierce rivalry has resumed as Boeing emerges from a two-year slump triggered by the grounding of its best-selling 737 Max. At the same time, it signaled a new challenge with the launch of a freighter designed to erode the U.S. group’s lead in air cargo.

“We see our competitor very willing to win campaigns, to ramp up production again,” CEO Guillaume Faury told Bloomberg Television. “At Airbus we enjoy that competition and we always try to bring the right products and services to our customers.”

Airbus lifted its guidance for full-year earnings, cash flow and aircraft deliveries, a day after Boeing posted its first profit in almost two years. The figures confirm a strengthening aerospace recovery that’s set to gather further momentum with sales campaigns at Air France-KLM’s Dutch arm and U.K. discounter Jet2, both of them usually loyal Boeing customers.

The new freighter, a version of the A350 passenger jet, is expected to enter service in 2025, Faury said on a media call, after the board granted approval for the project. The plane will be based mostly on the largest -1000 variant, and will have a payload of more than 90 metric tons.

The company gets “closer every day” to lining up launch customers, the CEO said. Boeing is meanwhile also eyeing a freighter launch, with CEO Dave Calhoun saying Wednesday his company hopes to launch a cargo version of the coming 777X “in the relatively near term.”

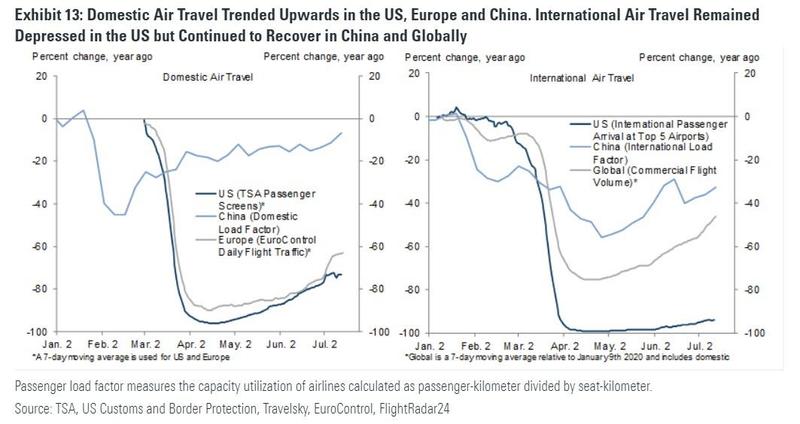

The improving outlook comes amid a travel reopening that’s gathering pace in some key markets.

Domestic Chinese and U.S. demand has led the comeback, the European Union has removed barriers to internal flights, and the U.K. this week announced that it will allow American and EU visitors who have been fully vaccinated to enter without self-isolating.

While other holdouts including Canada and Singapore are easing restrictions, long-distance routes that join continents are still restricted, holding back demand for bigger, more expensive wide-body aircraft.

Airbus expects to hand over 600 jets this year, up from as few as 566, helping to lift adjusted operating profit to 4 billion euros ($4.7 billion) — double the previous target — and generating 2.7 billion euros in free cash flow.

Boeing is also emerging strongly from the pandemic after it beat earnings and cash-burn estimates and Calhoun halted job cuts well short of the 20% originally planned.

Airbus announced a deal from German airline Condor for seven A330neos while detailing first-half earnings that beat estimates. Boeing last month scooped the lion’s share of a mammoth 270-jet order from United Airlines.

The KLM requirement for 160 aircraft will be a key battleground since sister carrier Air France is one of Airbus’s biggest customers.

Faury said Thursday that the company is having “very dynamic discussions” on potential orders and sees activity picking up toward the end of the year.

Still, both plane-makers will be dependent on key equipment manufacturers keeping pace with ramp-up plans, which at Airbus could reach 64 narrow-body jets a month by early 2023 and 75 by 2025.

Engine-maker Safran said Wednesday it expects a “small step up” in deliveries this year and questioned whether demand will support build rates above 60 a month.

From ZubuBrothers

Since returning the MAX 8 to service early this year, it seems barely a week has gone by without some new issue involving Boeing.

On Friday, Bloomberg reported that Boeing had notified airlines that it has discovered a new electrical issue with "a specific group" of Boeing 737 MAX jets.

Boeing has recommended 16 customers address a potential electrical issue in a specific group of 737 MAX jets before further operations.

The company recommended that its customers inspect the jets and verify that "a sufficient ground path exists for a component of te electrical power system."

The company is working with the FAA to address the issue and inform customers of specific tail numbers that will give them more direction to identify the problematic jets and fix the issue."

Boeing shares showed a slight reaction on the news, declining slightly on the news.

Which is puzzling because this isn't the first issue Boeing has had with its jets since returning the 737 MAX 8 to service.

From Zero Hedge

By Tyler Durden

On Thursday evening, the Federal Aviation Administration (FAA) said Boeing must inspect cabin pressure switches for thousands of its 737 jets worldwide that could lead to pilots becoming incapacitated, according to Reuters.

FAA's directive requires Boeing to conduct tests on all 737 series aircraft. There are more than 9,300 worldwide and 2,500 in the US. Inspecting cabin pressure switches will further ensure there's enough air to breathe as planes climb altitude.

The directive comes as three 737, all different series, last September, failed pressure switch tests. Defective switches could result in cabin altitude warning systems not activating above 10,000 feet, which would pose a safety risk to pilots and passengers. Dangerously low oxygen levels result in asphyxiation, then death.

The failure rate of the switches is "much higher than initially estimated" and poses a safety risk, the FAA said.

On all 737 series, tests must be completed within 2,000 flight hours since the last test of the switch.

The FAA is concerned the switches have a "higher than initially estimated" failure risk and poses safety issues.

On a worldwide basis, the FAA has no legal authority over airline carriers in different countries to enforce checks of the switches.

The words of the FAA are not encouraging for travelers who flood airports this summer after being cooped up in their homes during 2020 virus lockdowns.

The directive covers all versions of the 737, even the MAX, which has just recently been cleared to return to the skies in much of the world after being grounded for two years. In April, a new electrical issue developed on certain MAX jets.

Boeing shares premarket are slightly higher, though we should point out that the daily chart has yet to make a new high since March.

... and it has only been three days since Boeing revealed a new issue with the 787 Dreamliner widebody jet.

Boeing's quality control of its passenger jets has been lacking over for the last couple of years as the company focused on stock buybacks.

From Zero Hedge

If it's not one Boeing jet malfunctioning, it's another.

With Boeing facing an uphill climb in restoring the public's confidence in its crash-prone 737MAX, the aerospace giant is facing fresh troubles, this time involving the updated version of the long-haul 777X jet which is facing additional testing because of what U.S. regulators called a serious test-flight incident and multiple other issues with software and inadequate data.

In a sternly worded letter dated May 13, which was reviewed by The Seattle Times, the FAA warned Boeing it may have to increase the number of test flights planned and that certification realistically is now more than two years out, probably in late 2023.

According to the report, the FAA cited a long list of concerns, including a serious flight control incident during a test flight on Dec. 8, 2020, when the plane experienced an "uncommanded pitch event" meaning the nose of the aircraft pitched abruptly up or down without input from the pilots. During the incident, flight-control software triggered the plane to move without pilots’ input, similar to the malfunction responsible for the two 737MAX crashes.

Boeing has yet to satisfy the FAA that it has fully understood and corrected what went wrong that day.

An FAA official said the drag on 777X certification is now “the subject of a lot of attention” at high levels both within the agency and at Boeing.

“The FAA anticipates a significant impact to the level of regression testing, change impact analysis, and the potential to increase the number of certification flight tests that will need to take place,” the letter said according to Bloomberg. It was written by Ian Won, the acting head of FAA’s division overseeing Boeing.

The FAA said in the letter it now expected the certification wouldn’t occur until mid to late 2023 and the work would take “additional resources” that could hamper other projects with the company. While the FAA doesn’t set the timing of certification work, relying on companies for that, the letter suggests the program could face delays.

The latest delay will push the jet’s entry into commercial service into early 2024, four years later than originally planned.

Separately, the FAA also issued a statement Sunday saying it “will not approve any aircraft unless it meets our safety and certification standards.”

“Boeing remains fully focused on safety as our highest priority throughout 777X development,” a spokesperson at the U.S. planemaker said in a statement in response to the letter. “We are working through a rigorous development process to ensure we meet all applicable requirements.”

The harshly-worded letter by the FAA is the latest in what has been a deteriorating relationship between the giant planemaker and its U.S. regulator prompted by issues that arose during the grounding of Boeing’s 737 Max after two fatal accidents. The FAA had previously begun using its own inspectors to approve newly built single-aisle planes and has taken multiple steps to increase oversight of the company.

The FAA highlighted several concerns on the 777X, including a flight-control incident during a test flight on Dec. 8, 2020, when the plane experienced an “uncommanded pitch event.” That meant the nose of the aircraft rose or fell as a result of the control system.

A similar issue triggered by a malfunction on the 737 Max pushed down that jet’s nose repeatedly during the two crashes that killed 346 people, prompting a sweeping review of how pilots interact with increasingly computerized flight-control systems. The Max was grounded for 18 months while it was redesigned.

Bloomberg adds that the agency also told Boeing that a critical avionics system proposed for the airplane doesn’t meet requirements and expressed concern about proposed modifications involving late changes to both software and hardware in the electronics of the jet’s flight controls.

Worse, in a hint of broader troubles for the 777X, the FAA said that European regulators are uneasy over parts of the plane’s design. “The European Union Aviation Safety Agency has not yet agreed on a way forward on the Model 777-9,” the FAA said in the letter. Which, of course, is understandable for a European regulator that would be delighted with pushing out its own competitor Airbus planes.

Boeing announcement in January that it was postponing the 777X’s planned market entry to late 2023 was the latest in a string of delays for a jet originally slated to begin commercial service last year. Executives also disclosed that they were redesigning the jet’s actuator-control electronics at the behest of European regulators.

"That’s still the plan", Boeing’s Chief Executive Officer Dave Calhoun indicated in a June 3 presentation, weeks after the FAA letter.

“That airplane, we are still confident will be certified in the fourth quarter of 2023,” Calhoun told a virtual Bernstein conference. The planemaker reset its timeline based on the 20-month review of the 737 Max and “architectural preferences” of both the FAA and EASA, he said.

“So those are the important things with respect to how we do this,” Calhoun said. “We’ve given ourselves time to learn as we go through this.”

Emirates President Tim Clark has repeatedly slammed Boeing for delaying the 777X program and has raised concerns over the model’s performance in desert conditions. Bloomberg reported in February that Clark’s airline could swap as many as a third of its 115 commitments for the 777-9 to the smaller Boeing 787 Dreamliner.

From BBC

By Theo Leggett

Business correspondent, BBC News

Little more than six months after Boeing's 737 Max was cleared to fly again by US regulators, the aircraft finds itself under intense scrutiny once again.

The discovery of a potential electrical problem last month led to the renewed grounding of more than 100 aeroplanes, belonging to 24 airlines around the world.

Deliveries of many more new aircraft have been suspended. Boeing and the US regulator, the Federal Aviation Administration say they are working closely to address the issue.

But the affair has given new energy to critics who claim the 737 Max was allowed back into service prematurely - and that issues which could have contributed to two fatal crashes have not been fully analysed or addressed.

Those critics include a high profile whistle-blower, Ed Pierson, who has already sought to link allegedly poor production standards at the 737 factory with electrical defects on the crashed planes, which he claims may have been implicated in both accidents.

According to Boeing and the FAA, the problem first became apparent during testing of a newly manufactured 737 Max 8, which had yet to be delivered to its owner. It was found that electrical power systems on the aircraft were not working correctly.

The fault was traced to poor electrical bonding, where panel assemblies that were also intended to conduct electricity and form part of a connection with the frame of the aircraft were not doing so effectively.

This meant that some components on the plane, including the pilots' main instrument panel and a standby power control unit, were improperly grounded, or earthed.

According to the FAA, this could potentially "affect the operation of certain systems, including engine ice protection, and result in loss of critical functions and/or multiple simultaneous flight deck effects, which may prevent continued safe flight and landing".

The flaw, then, was a dangerous one. The FAA was worried that over time other aircraft, which were already in service, could develop the same condition. It issued an Airworthiness Directive on 30 April stipulating that affected aircraft should be modified before being permitted to fly again.

On the face of it, there is nothing to link these flaws with the errant flight control software - known as MCAS - that triggered the loss of two planes, in Indonesia and Ethiopia, claiming the lives of 346 people.

In each of those accidents, flawed data from a faulty sensor prompted MCAS to force the nose of the aircraft down repeatedly, when the pilots were trying to gain height, ultimately pushing it into a catastrophic dive.

It occurred, he says, because in early 2019, Boeing changed the way panels were attached on parts of the plane. It was seen as a very minor change, so it was not notified to regulators.

"There was nothing, let's say, unethical about that", he explains. "Prima facie, this appears to be an honest mistake, the implications of which have just been unearthed".

But for Mr Pierson, a former senior manager on the 737 production line, the new electrical issues are a symptom of something more serious.

During congressional hearings into the crashes involving the Max, he claimed that in 2018 the factory in Renton, near Seattle had become "dysfunctional" and "chaotic", as pressure increased to produce new aircraft as quickly as possible.

Earlier this year, he published a report that explicitly linked alleged production pressures with electrical anomalies and flight control system problems that occurred on both crashed aircraft prior to the accidents.

He now says the disclosure of new problems reinforces his case.

"Yes, MCAS caused the airplanes to pitch down and crash", he explains. "But it was an electrical system malfunction that likely caused the angle of attack sensor to send faulty data to MCAS".

Mr Pierson believes that the 20-month recertification process which cleared the 737 Max to fly again focused on software design and pilot training, but failed to address the impact of production standards at the factory.

As a result, he says, it is "no surprise that new discoveries linked to 737 Max production defects continue to come to light" on an aircraft described by the FAA's Administrator Steve Dickson as "the most scrutinised transport aircraft in history".

Mr Pierson says he has written to the US Transportation Secretary, Pete Buttigieg, requesting a meeting to outline his concerns, but has not heard back.

Boeing emphatically denies any connection between production standards in the 737 factory and the two accidents involving the 737 Max.

It says: "The Lion Air and Ethiopian Airlines accidents have been reviewed by numerous governmental and regulatory entities, and none of those reviews has found that production conditions in the factory contributed to the accidents."

Dai Whittingham is chief executive of the UK Flight Safety Committee, a group of organisations, including airlines and regulators, which promotes safety in commercial aviation.

He says that a direct link between the two accidents and the recently-discovered electrical flaws is "a hard connection to make".

But on one key point he appears to agree with Mr Pierson. "These issues are separate in how they've arisen", he explains, "but they may well have stemmed from the same corporate culture, with a focus on saving time and keeping costs down over maintaining quality".

The allegation that Boeing prioritised profit over safety in the run up to the two accidents is not new - and indeed was made by prosecutors when announcing a $2.5bn settlement with the aerospace giant earlier this year.

The company says it has learned many lessons as a result of the Ethiopian Airlines flight ET302 and Lion Air 610 accidents. It says it has "made fundamental changes" and continues "to look for ways to improve".

"Boeing is committed to restore trust, and we'll do it one airplane at a time," it said.

People within the company insist the changes which led to the current problems were not motivated by time or cost savings.

It's not clear how long the affected aircraft will remain grounded. The actual modifications required are expected to be relatively simple and are only expected to cost about $2,250 (£1,600) per aircraft. But the FAA is understood to be asking for detailed analysis to be sure all potential concerns have been dealt with.

With the scrutiny the 737 Max is under, neither Boeing, nor the FAA, can afford to make a mistake.

From Zero Hedge

By Tyler Durden

Boeing's troubled 737 Max returned to US skies last month. American Airlines was the first domestic carrier to fly the Max and has since operated more than 200 flights. While other domestic and international carriers gear up for a much wider re-launch of the aircraft, a former senior manager at Boeing's 737 Max plant in Seattle has published a new report warning that the Max is "still not fixed."

Ed Pierson, the report's author, retired from Boeing in August 2018 and worked at the Max factory in Renton, Washington, claims more investigations are needed into the aircraft's electrical system and production quality problems at the factory.

Pierson alleges that the US and European regulators have primarily ignored factors that he points out in the report, which may have played a role in Lion Air flight JT610 and Ethiopian Airlines flight ET302 crashes that killed 346 people. He links both crashes back to conditions at the factory in Renton.

Pierson firmly believes Boeing's effort to redesign Max's flight control system, called MCAS software, ensures a single sensor failure would not happen in flight is not enough.

"The paper underscores the likely role a chaotic and dangerously unstable production environment played in the accidents. Mr. Pierson also puts forth three other plausible accident scenarios not addressed in the accident investigations. The 14-page report includes a timeline and an analysis that ties the two 737 MAX airplane crashes together in ways not previously reported. Most importantly, Mr. Pierson's analysis raises serious doubts as to the safety of the 737 MAX. Alarmingly, the FAA's recertification fixes do not address the problems identified in the report," the report's abstract reads.

In late 2019, Pierson testified during a House Transportation Committee hearing on both Max crashes where he described the Renton factory as "chaotic" and "dysfunctional."

With the planes returning to the air, he is worried that Boeing and regulators have overlooked many of the issues he pointed out.

In the report, he believes the production defects of critical Max parts were defected when they entered service, adding that the aircraft's complex wiring systems may have contributed to the random deployment of the MCAS system in flight.