From Zero Hedge

European And Middle Eastern Regulators Raise Scrutiny Of 777X As Confidence In Boeing, FAA Plummets

By Tyler Durden

In the latest blow to Boeing, whose sagging shares are helping to weigh on the Dow in Wednesday's thin pre-holiday trade, WSJ has published a story claiming that regulators in Europe and the Middle East are ratcheting up their scrutiny of the new 777x. The news followed a report about a failed stress test by mere hours.

The move marks the end of an era for American aviation, when international regulators simply trusted the US to handle oversight. It's an important sign of the confidence that has been lost as Boeing struggles to move on from the crashes, and mass groundings, of the 737 MAX 8.

The European Union Aviation Safety Agency said in a statement it is performing a “concurrent validation” of the FAA’s certification of Boeing’s 777X, a new variant of the company’s popular wide-body jet. The plane is expected to be the first new airliner design from either Boeing or rival Airbus SE to come to market since the MAX crisis began. Two recent crashes of that jet exposed problems with its flight-control systems and FAA certification procedures. Regulators around the world grounded the entire fleet, creating turmoil for airlines and passengers world-wide.

The national regulator in the United Arab Emirates, meanwhile, also plans to separately scrutinize the certification process of the 777X, according to people familiar with the matter. While a small agency, the Emirati General Civil Aviation Authority wields outsize influence over the future of the 777X. That is because the U.A.E.’s state-owned carrier, Emirates Airline, is one of the new jet’s biggest customers. It is slated to be the first airline to fly the airliner in 2021.

According to WSJ, the regulators aren't insisting on performing their own complete independent certifications, rather, they're going to scrutinize the process used by the FAA.

European and Emirati regulators aren’t envisioning a full-blown certification of their own. Instead, they will independently scrutinize the processes used by the FAA and Boeing related to a number of specific systems on the plane, including its flight-control system and Boeing’s safety classification system, according to people familiar with the matter. They will also individually review the plane’s unique folding wings, these people said.

These reviews are perhaps the clearest sign yet that the FAA's status as the world's most reliable regulator has been lost, something that President Trump will need to blame on President Obama.

The separate reviews further undercut the FAA’s once-unchallenged stature as the world’s most influential regulator. The agency had lost credibility in the days after the crash of an Ethiopian Airways 737 MAX in March. That followed the deadly crash of a Lion Air MAX, under similar circumstances, late last year. The crashed killed 346 people in total.

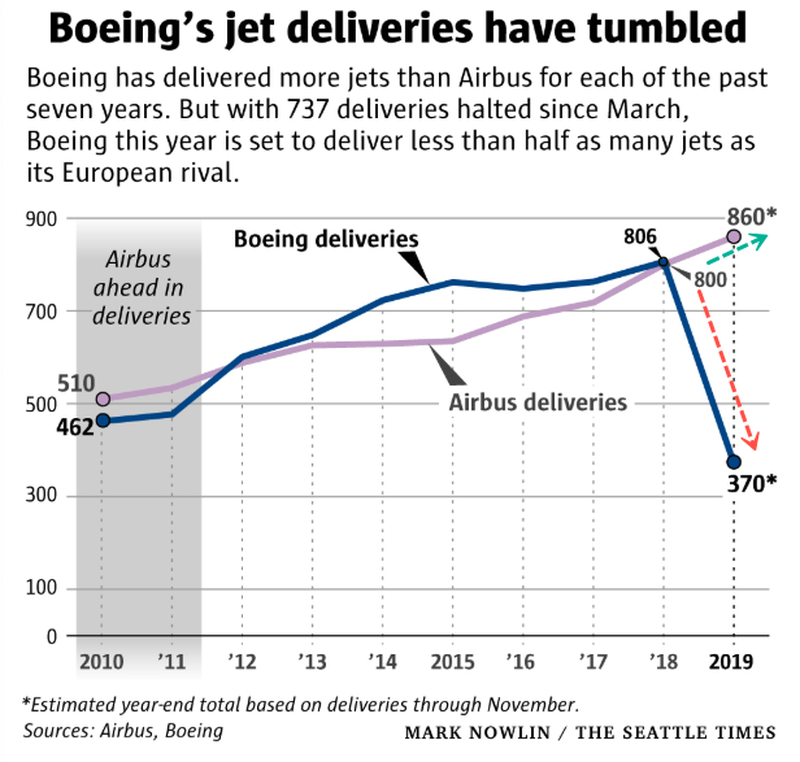

There's no question that this is terrible news for Boeing, Fortunately, according to the latest reports, the 737 MAX should be back in the skies by early next year.

* * *

With the FAA reportedly preparing to inspect every 737 MAX individually before it signs off on the planes' return to the air - a decision that will likely delay recertification and add to Boeing's losses - the latest bad news for the aerospace firm comes from its hometown (well, sort of, Boeing is officially based in Chicago but the bulk of its operations are located in Washington State) paper, the Seattle Times.

The paper reported that a recent stress test for a new model of the Boeing 777 resulted in the fuselage (a fancy term for the body of the plane) ripping apart just below the FAA's official threshold for certification.

Driving the story home, the paper also published a grainy cellphone pic of the damage:

Back in September, the ST and a few other outlets reported that there were problems with the stress test, and that a door had flown off the handle. This, as it turns out, is not only incorrect, but it minimizes the seriousness of what actually happened.

During the test, the plane's fuselage "split dramatically" along the underside of the plane near where the landing wheels are stowed. The body of the plane was rent open with the force of a bomb. Workers in another hanger nearby said the ground the shook and they heard a load explosion. The Seattle Times clarified that their earlier reporting about a door flying off its hinges was mistaken: the 777's doors close from the inside and are larger than the holes they cover, but one door was seriously damaged.

When Boeing tested the original 777 model in 1995, it kept going until the aluminum wings snapped at 1.54 times limit load. On the 787, it chose to stop at 1.5 and then ease the composite wings back down again. Breaking a pair of composite wings could result in release of unhealthy fibers in the air, so it’s likely that with the 777X also having composite wings, that was the plan again this time.

But as Boeing personnel along with six FAA observers watched from the windows of a control room, at 1.48 times limit load - 99% of ultimate load - the structure gave way. Under the center fuselage, just aft of the wing and the well where the landing gear wheels are stowed, the extreme compression load caused the plane’s aluminum skin to buckle and rupture, according to the person familiar with the details.

The resulting depressurization was explosive enough that workers in the next bay heard it clearly. One worker said he heard “a loud boom, and the ground shook.”

Then there was the secondary damage...

That then caused secondary damage: The photos show that the fuselage skin split part of the way up the side of the airplane, along with areas of bent and twisted structure that extended through the area around a passenger door.

A day after the incident, based on incomplete information, The Seattle Times and other media outlets incorrectly reported that a cargo door had blown out.

Unlike the plane’s cargo doors, which hinge outward, the passenger doors on airliners are plug-type doors that only open inward and are larger than the hole they close. But the structure around that passenger door just aft of the 777X wing was so damaged that the pressure blew the door out and it fell to the floor.

These secondary damage sites — the rip up the side of the fuselage, the door blown out — alarming as they might seem, are not a concern to air safety engineers. “The doors were not a precipitating factor,” said the person familiar with the details.

It’s the initiating failure, the weakness in that localized area of the keel, that Boeing must now fix.

As uncomfortable as it sounds, Boeing probably won't need to do a retest: Since the rupture occurred so close to the threshold level, the FAA will likely allow Boeing to make the necessary changes independently and then show its work via analysis.

A safety engineer at the Federal Aviation Administration (FAA), speaking anonymously without permission from the agency, said that because the blowout happened so close to the target load, it barely counts as a failure.

Boeing will have so much data gathered on the way to the 99% stage that it can now compare with its computer models to analyze the failure precisely, the FAA engineer said. It can then reinforce the weak area, and prove by analysis that that’s sufficient to cover the extra 1%.

One engineer said the rip actually isn't anything to worry about.

The engineer said it’s not that unusual to find a vulnerability when taking an airplane structure to the edge of destruction.

"The good news is they found it and can address it," the FAA engineer said. "They found a problem they can fix. They can beef up the structure based on analysis."

And here are some more details about the test, including an explanation of the FAA's standards, as well as what happens to the test plane during the test.

The test conducted that day was the final test of this airplane, which was fixed in a test rig inside the Everett factory specifically to be stressed close to destruction. The jet was surrounded by scaffolding and multiple orange weights hung from the airframe. Wires were hooked to instrumentation that studded the surface to measure every stress and deflection, the data monitored in real time by engineers sitting at control room computers.

As the test neared its climax, weighted pulleys had bent the jet’s giant carbon composite wings upward more than 28 feet from their resting position. That’s far beyond the expected maximum deflection in normal flight of about 9 feet, according to a person familiar with the details.

At the same time, the fuselage was bent downward at the extreme front and aft ends with millions of pounds of force. And the interior of the plane was pressurized beyond normal levels to about 10 pounds per square inch — not typically a requirement for this test, but something Boeing chose to do.

All this simulated the loads in a flight maneuver where a pilot would experience a force of 3.75 G, compared to the maximum of 1.3 G in normal flight.

The combination of the bending forces on the wing and fuselage created a high compression load on the bottom centerline of the fuselage — the keel — according to the person, who asked for anonymity because the details are sensitive.

Federal certification regulations require engineers to ratchet up the forces until they reach “ultimate load” — defined as 1.5 times the “limit load,” which is the maximum that would ever be experienced in normal flight — and hold it there for at least three seconds.

Unfortunately for Boeing, traders weren't in the mood for excuses, and sent the company's shares lower in premarket trade...even as the broader market was set to open at record highs.

During the APU engine start, the IGV (Inlet Guide Vanes) are supposed to be closed. This allows all incoming air to be directed into the combustion chamber. After start with a air demand (main engine start or air conditioning pack operation), the IGV vanes open allowing bleed air output.

During the APU engine start, the IGV (Inlet Guide Vanes) are supposed to be closed. This allows all incoming air to be directed into the combustion chamber. After start with a air demand (main engine start or air conditioning pack operation), the IGV vanes open allowing bleed air output.