| Megger |

||

|

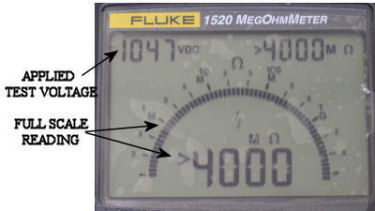

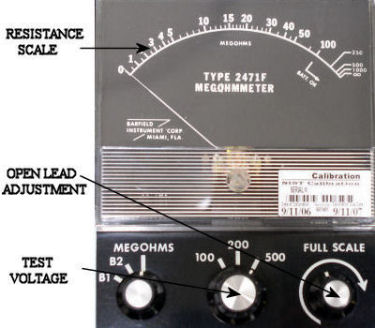

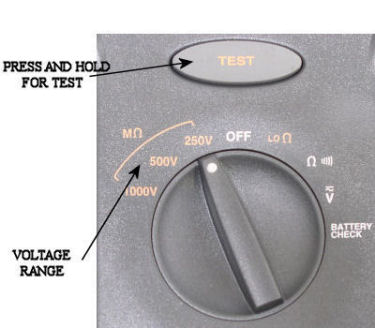

The Megohmmeter or Megger is a great tool for verifying wire to ground or wire to wire shorts. It applies a high voltage DC potential across the wire(s) under test. The megger will show shorts that would not be known using a regular Volt/Ohm meter.

The ABSOLUTE first step before using a megger is to verify per the wiring prints that ALL associated components have been isolated from the wire under test. Neither analog nor digital circuitry enjoy 250-1000 VDC being thrown at it and most components will not survive a hit from a megger.

Never use a megger to verify a “in tank” fuel quantity harness problem.

Digital meggers do not require any adjustment to use. Older analog units have an open lead (tests leads not connected) full scale adjustment. Adjust this to maximum or infinity (∞) before use. This adjustment will change with the different test voltages.

I like to start at the lower voltage settings to check wires. A megger will supply a high voltage potential, but very little current, it is still good practice to start low and then move higher if needed. A good check indicates as close to maximum (∞) as possible

|

|

|

|

||

|

Tips for Megger Testing

|

||

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE. APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

||

| Fuel Quantity Test |

|||

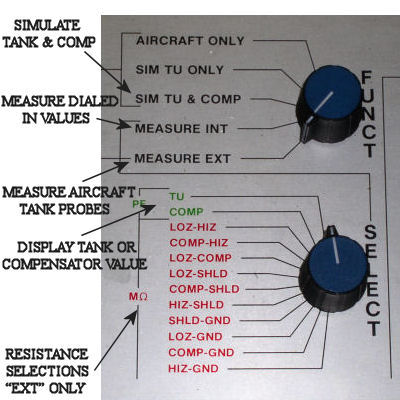

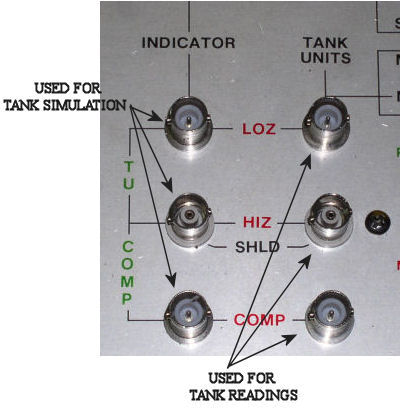

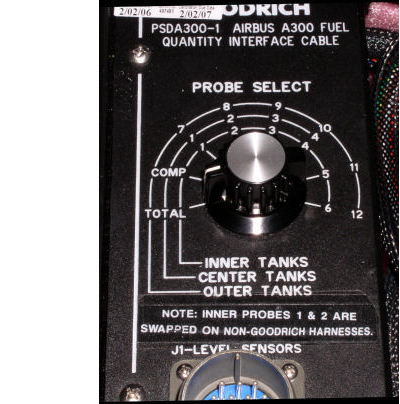

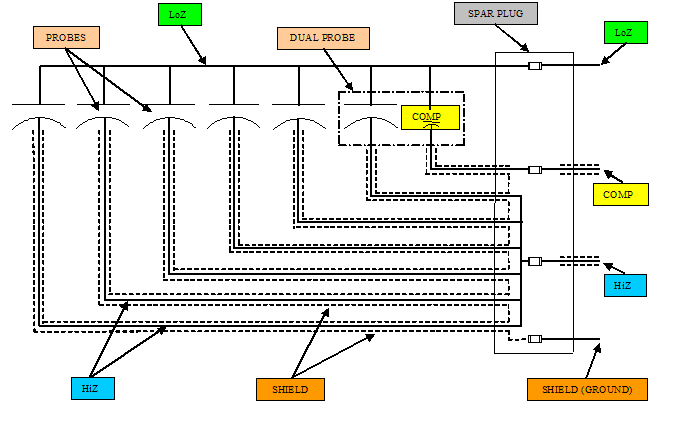

| Aircraft fuel quantity indications are capacitance based systems. Troubleshooting and calibration of these systems is accomplished with the Fuel Quantity Test Unit. The tester measures tank and probe capacitance, accomplishes resistance checks, and provides simulation for tank quantity indication. | |||

|

STARTING WITH THE BASICS

FUEL TANK CAPACITANCE CHECKS

Fuel quantity test boxes are made by numerous manufactures. All will have similar switches and functions. The tester shown here is JcAir® “PSD60-2R.

TANK SIMULATION

|

|

||

|

|||

|

|||

|

|||

|

|||

|

Helpful Tips for Fuel Quantity Testing

|

|||

|

|||

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE. APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

|||

| Watt Meter |

||

|

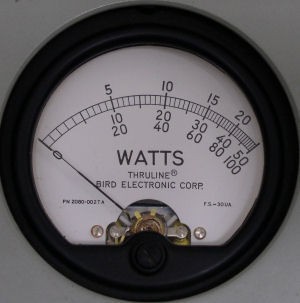

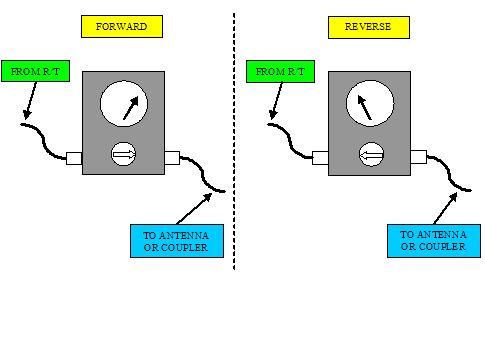

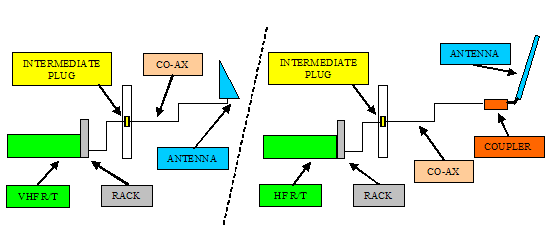

The Watt Meter is used to verify the operational integrity of VHF and HF transmission co-ax and antenna systems. It checks forward and reverse power of audio transmissions. The indication result is often referred to as SWR or Standing Wave Ratio.

Aircraft voice communication radios, VHF (118.00MHz – 136.00MHz) and HF (2.0MHz – 29.9999MHz), require the transmission system to dissipate the maximum amount of the transmitted signal. No system is perfect, so there always will be a feedback of some of the signal. If this feedback is within acceptable minimum limits the VHF and HF transceivers will provide proper communication functions. When the co-ax or antenna installation as been compromised, the majority of the transmitted signal will not be radiated from the antenna. This power must go somewhere, so it will travel back down the co-ax to the R/T. The flight crew will report poor or inop transmissions. If the problem is not found and corrected, the result will be numerous R/T replacements and continued pilot write-ups.

The watt meter is placed "in-line" with the co-ax run. Placing it in the system requires one or two extra co-ax jumpers and a connector adapter kit to match the jumper(s) with the different types of aircraft connectors. It also requires the correct "slug" to be installed in the meter. For VHF, the slug is usually 100MHz – 250MHz with a 25 -50 watt rating. HF slugs are 2MHz – 30MHz with a minimum of 200 watt rating. The arrow on the slug "points" down line towards the antenna for forward power and to the R/T for reverse power. With the affected radio selected and microphone keyed, the forward or reverse power can be measured. Typical aircraft VHF radios output approximately 15 watts. HF radios transmit around 150 watts.

|

|

|

|

||

|

|

|

|

Helpful Tips for Watt Meter Usage

|

||

|

||

|

||

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE. APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

||

| Buzz Box |

||

|

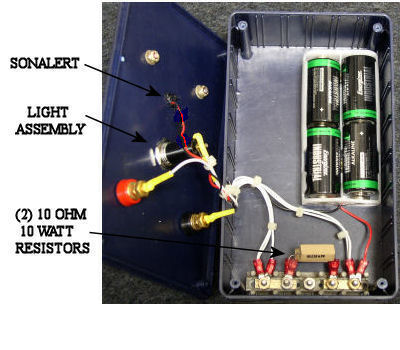

A buzz box is used to apply a current load on a wire. A wire that is hanging on by a couple threads will check good with a ohm meter, but it might not be able to carry the required load.

A buzz box can be built to apply almost any amperage. The box shown here will put approximately 1 amp across a wire. A 22 gauge or larger wire can safely handle 1 amp for testing. 24 gauge wires, which are about the smallest installed on aircraft, are mainly used for signals. Putting 1 amp across a 24 gauge wire is not a good idea. On the rare occasion where a larger wire needs to be loaded, aircraft bulbs used with 28 volt battery power are a good way to load a wire. Medium sized bulbs such as a runway turnoff or wing illumination light will put a hefty load on a 14-16 gauge wire.

The buzz box or light is going to accomplish one of two things, either the wire will carry the load or it will burn through. If a wire goes open, it is easier to find and correct the problem.

All the components for this box were purchased from Radio Shack®. The resistors, light, and sonalert are wired in "series". The wire under test completes the circuit. |

|

|

|

||

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE. APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

||

| Easy 28 |

||

|

It might look cheap, but if a quick supply of 28 VDC is needed, it works great. This is mainly used as a "off aircraft" tester for relays, solenoids, and bulbs. Power is limited, using it on larger items is not recommended.

Having a bench 28 VDC power supply available for testing is still the preferred method.

|

|

|

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE. APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

||