Sometimes a meter can be your worst enemy.

We had a inoperative forward cargo door indication that several stations had addressed. The system (should be) quite simple to understand. One door switch and one handle switch, along with three grounds. Seems simple enough, but for a while there I thought some men in white coats with a special jacket were coming for me.

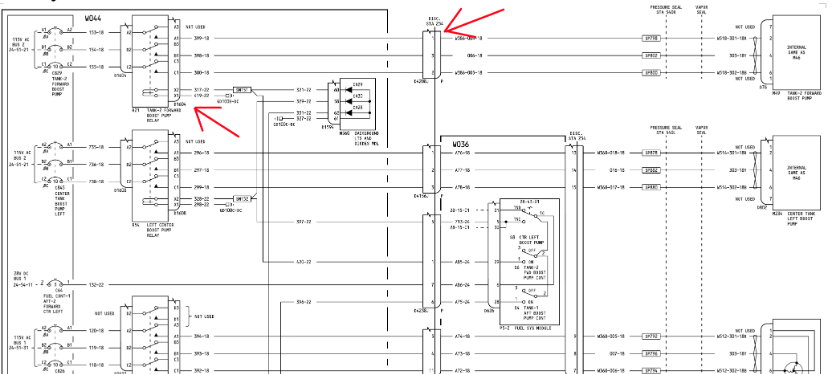

What we had was somewhat strange. With the door hanging open and the handle down, we had a green indication...... not right. We did have a normal green for the door closed and handle up. We could only get a amber with the door open and the handle up. Normal amber comes from "either" the door open or handle down.

We also had Flight Warning Computer "Fwd Cargo Door Switch" faults.

(Crappy picture.... sorry)

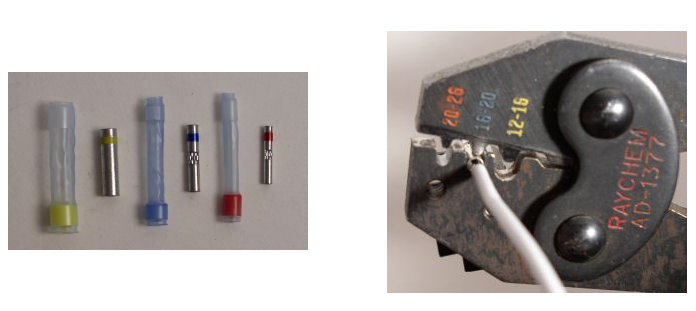

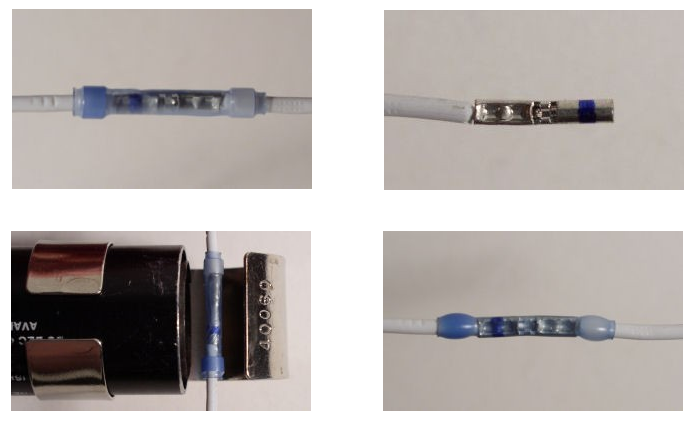

We went for the most likely problem area first. With the door open, we cut the wrapping off the frame-to-door harness. One busted wire and one right on the edge. We fixed them both.

Problem repaired???? Hell no. We probably broke the wire opening up the harness, but repairing them "should" prevent future breaks. At least for a while.

Time to open some crap up and grab a meter. We took the forward right ceiling off to gain access to terminal block 4004VT

As a precursor, both the #1 FWC and the SDAC were seeing the fault. The FWC receives all three grounds for its circuitry, but the SDAC only looks at one. If both computers were seeing a problem, it was most likely on the one wire that fed them both.

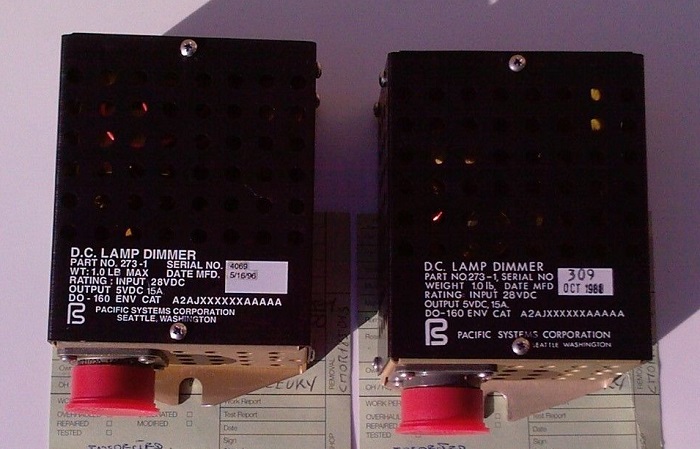

Two FWC's, blue on top - SDAC, single black box below.

These are just grounds we're looking for, but the meter was all over the place. Good continuity, 7K ohms, 14M ohms. Shut the handle, shit changes. Make the door switch, more weird readings. OK... off come the door panels to get to terminal block 4002VT.

To eliminate door harness wiring I made a jumper.

No help. Finally... after three hours of dicking with this thing, I decided to remove the two suspect wires from pins "B" and "G" of block 1 on 4002VT. I used a jumper to hook them together........ The problem went away!!!!

Solution.... replace a shorted out terminal block. The two pins in question were shorted out to one or more of the adjacent pins. Thus the screwed up meter readings. The door has no insulation in this area, so that terminal block has been frozen a thousand times over. It finally gave out.

I'll keep this fix in the memory bank for a while.

A300-600 ASM 52-71-00

AWM 52-71-02