| VOR Test |

||

|

The use of VOR systems as primary navigation is diminishing on most modern aircraft. GPS and FMS installations provide more reliable and direct routes for flight. The end of VOR use is not in the near future. When used along with DME, VOR systems provide very accurate FMS position computation over land.

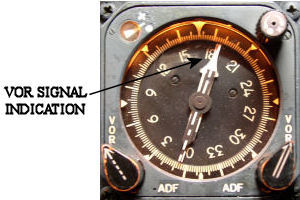

Testing of a VOR system is similar to ILS. Both use the HSI deviation bar as indication. Unlike ILS, VOR is referenced to compass input. One of 360 course selections can be dialed in. Each dot represents 5 degrees when the deviation bar is off center. Most RMI's are equipped with VOR/ADF needles. When selected to VOR, these needles will point TO the tuned VOR station.

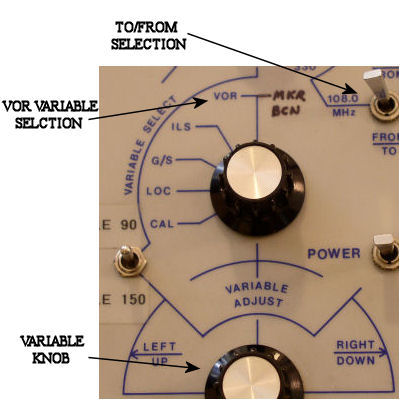

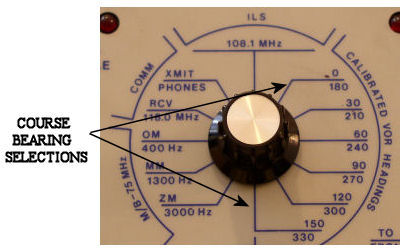

The standard VOR test box signal is 108.00 MHz. The variable function allows for simulation of all 360 radials. As an example: with the test unit simulating 140 degrees, numerous results should be observed. With the HSI course selected to 140, the deviation bar should be centered and the to/from arrow pointing the direction of the selected course. The GS Indicator should be "biased out of view" and both the VOR/LOC or GS flags should be pulled. The variable knob can be used to move the deviation bar left and right of center. Flipping the to/from switch will cause the to/from arrow in the HSI to point opposite the selected course.

|

|

|

|

|

||

|

|

||

|

|

||

|

|

||

|

Helpful Tips for VOR Indication and Testing

|

||

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE. APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

||