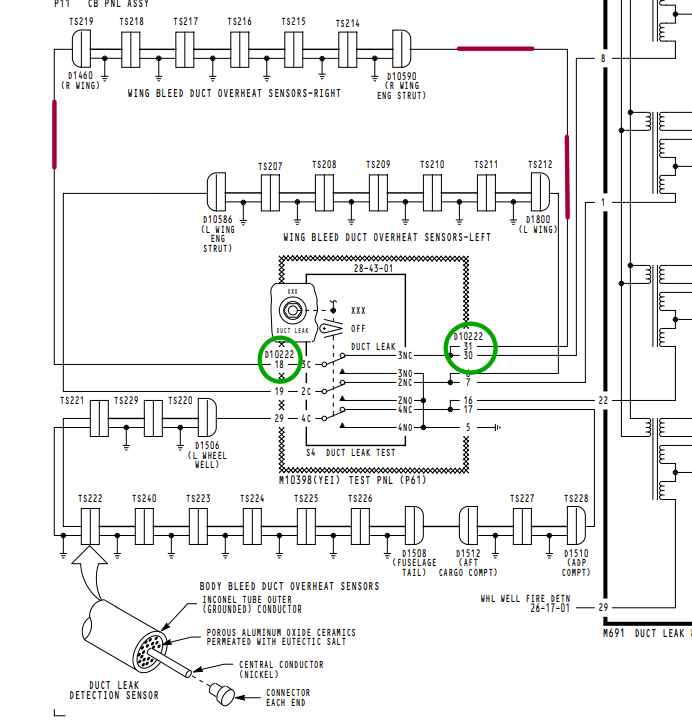

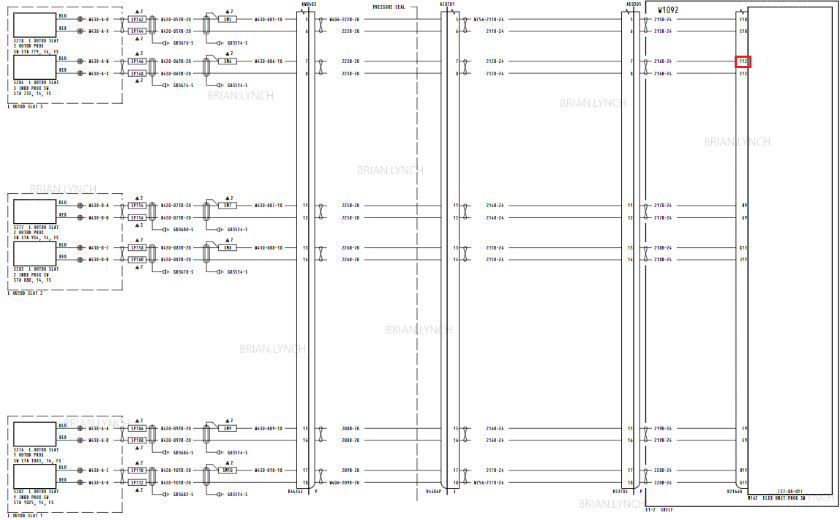

Some confusion has been generated when comparing Maintenance Manual proximity sensor requirements and actual readings.

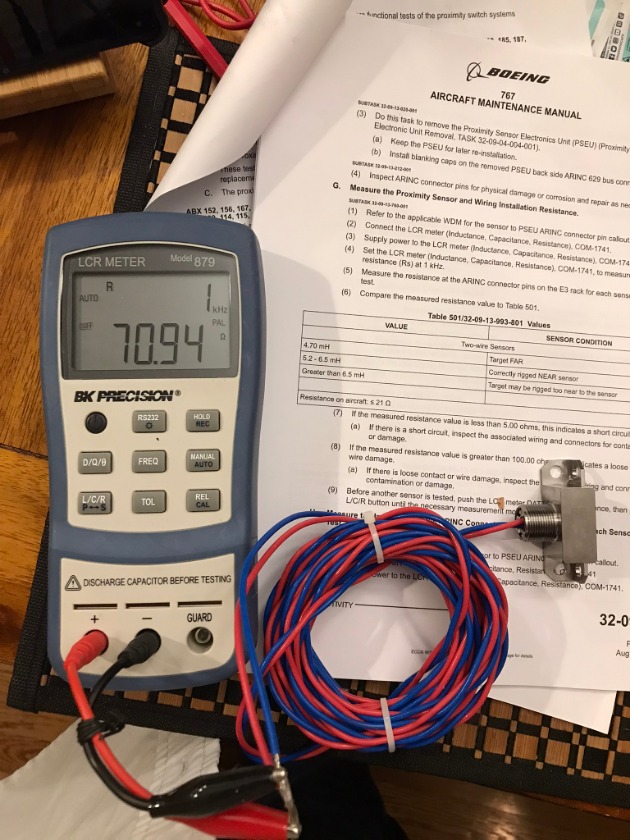

From B767 AMM, 32-09-13.

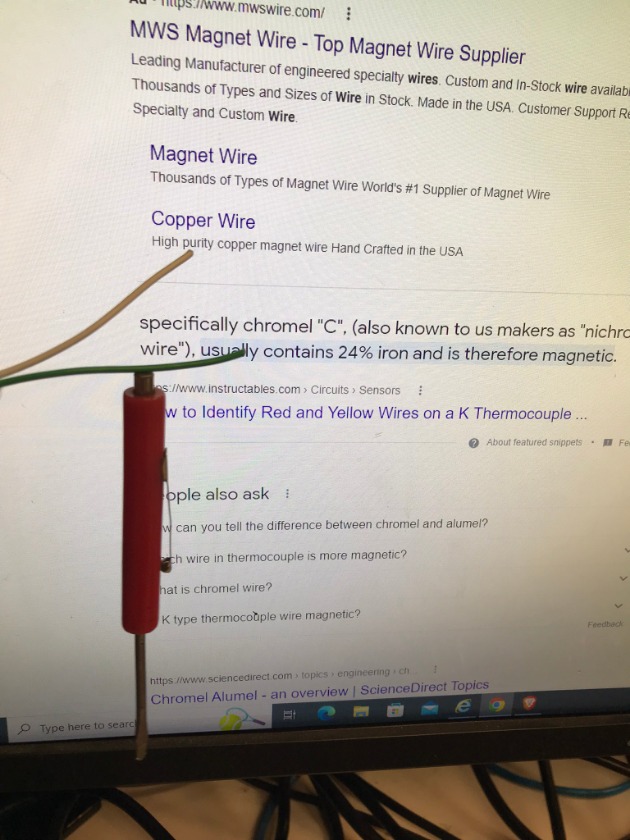

Boeing asks for resistance in the first chart and then states that readings are in mH or Millihenry. Millihenry is a measurement of inductance, not resistance. In the second chart they ask for inductance and resistance, but the readings don't come close to what our meters are showing.

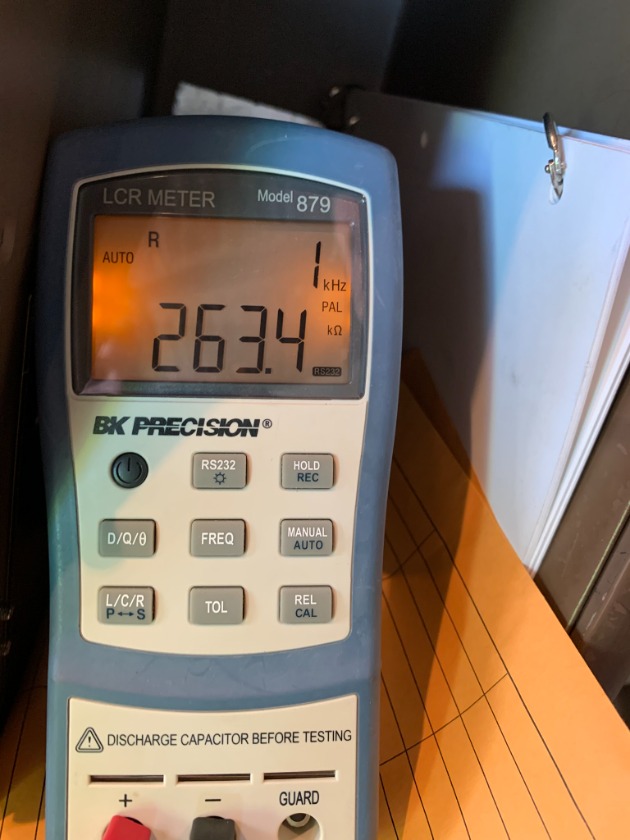

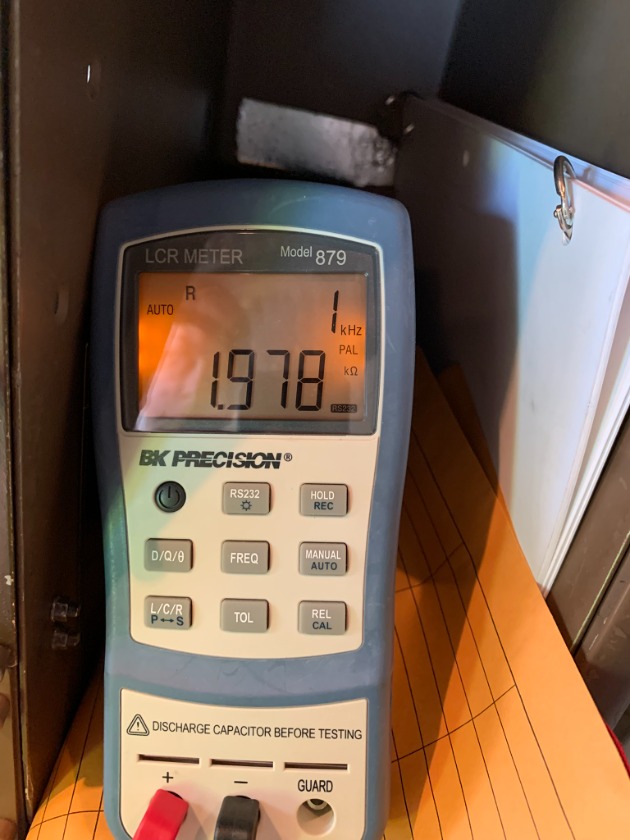

Resistance with the LCR meter is way out of anything stated by the manual. I'm going to trust our readings before the manual. The following images show actual results on the aircraft and in the shop.

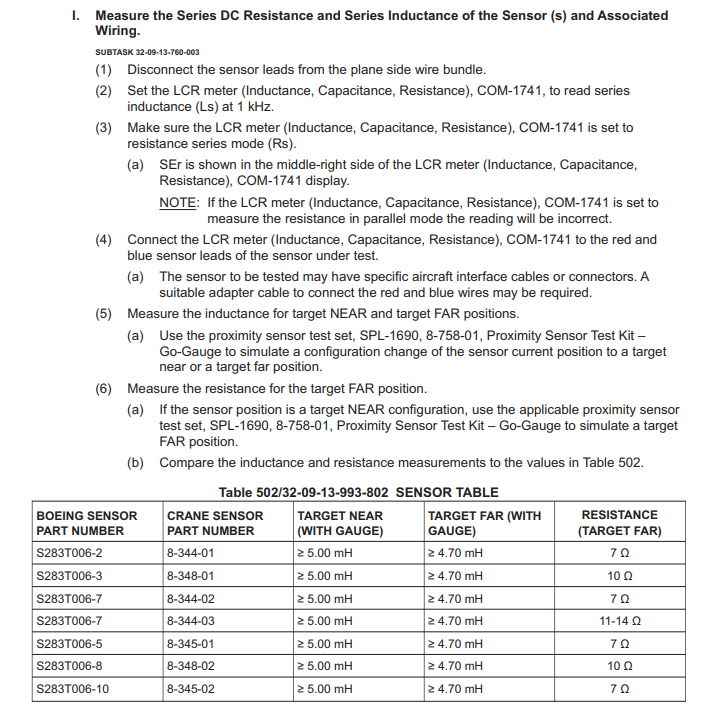

With the LCR in inductance set at 1KHz and the target far.....

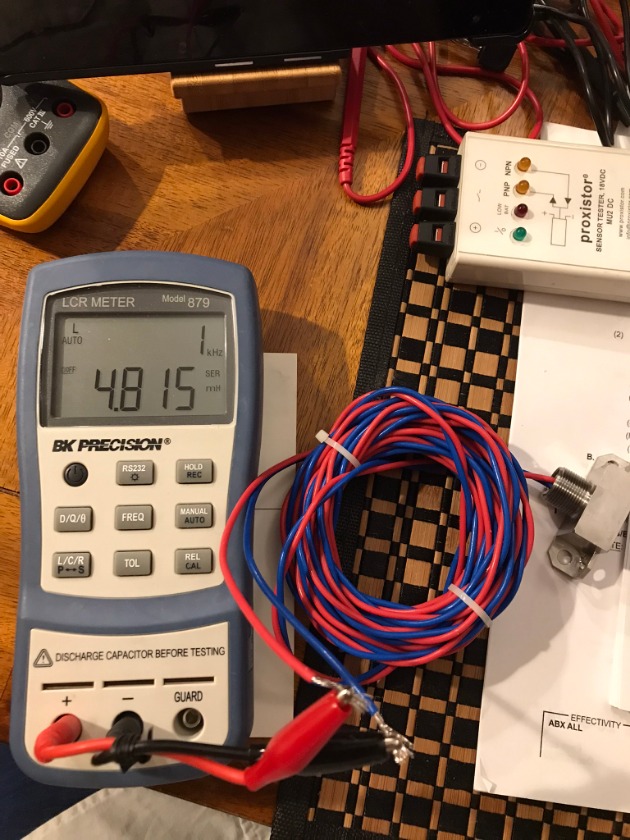

Target near (using a folded napkin for spacing).....

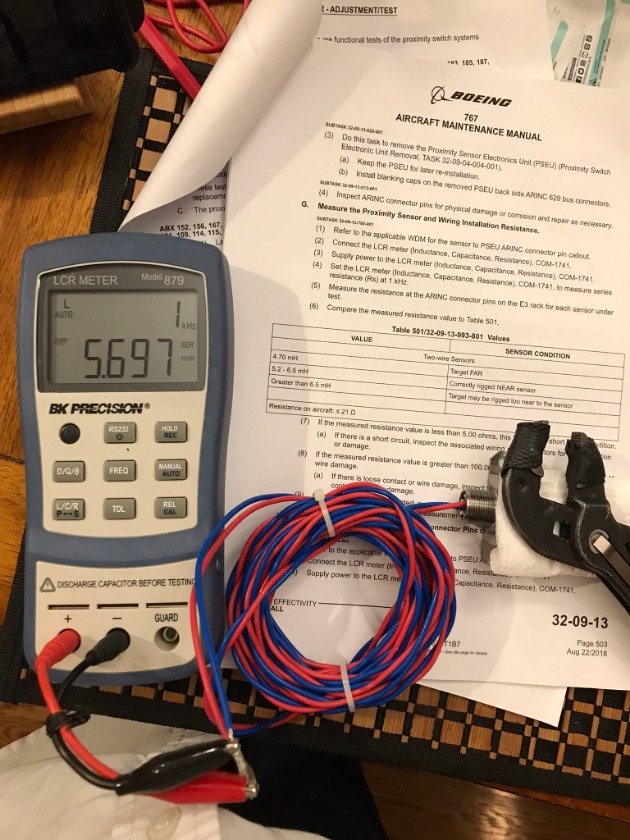

Target touching.....

Resistance using LCR.....

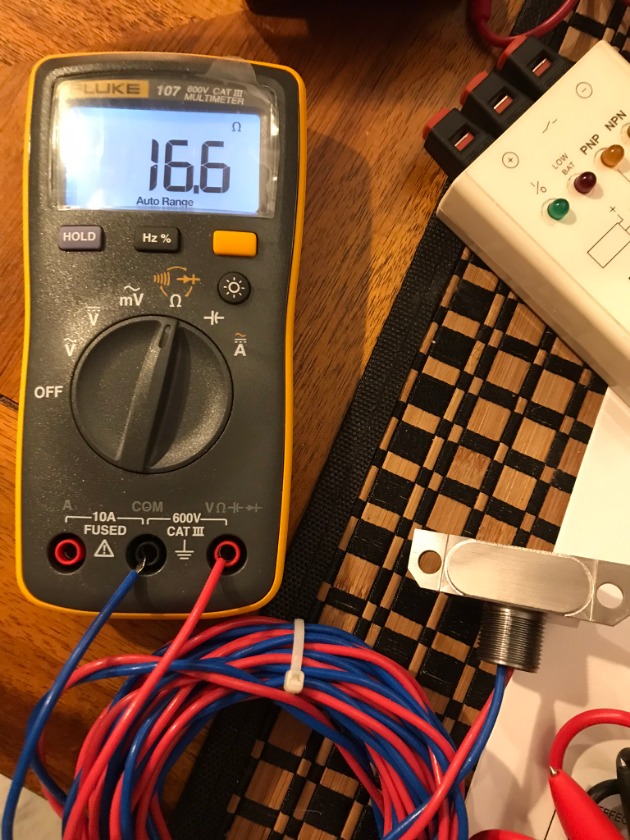

Resistance using VOM.....

In the case of targets near and far, these seem to fall within the readings shown in the first chart. As to what might cause the PSEU (Proximity Sensor Electronics Unit) to fail a sensor, we'll have to experiment on an aircraft one day. I would guess that laying a target directly on the sensor causing a high mH reading should be a failure.

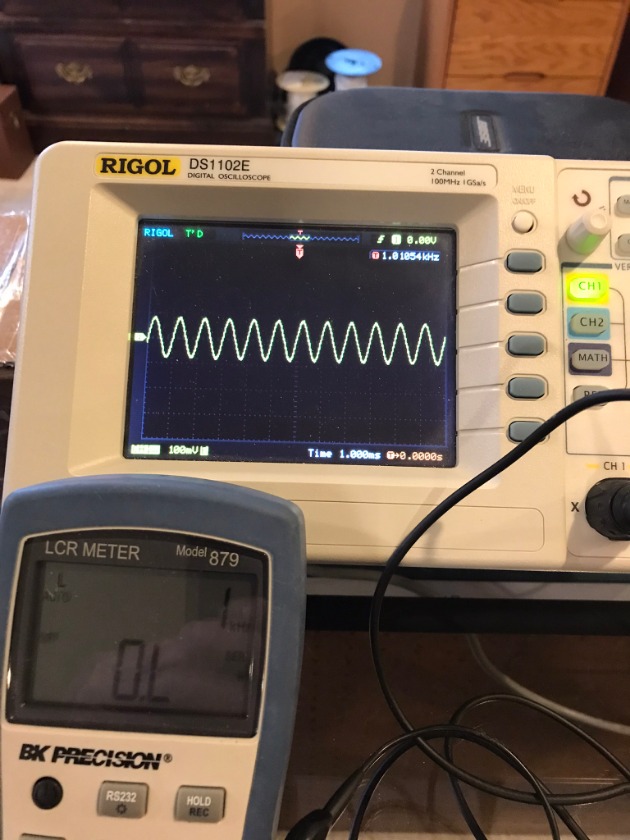

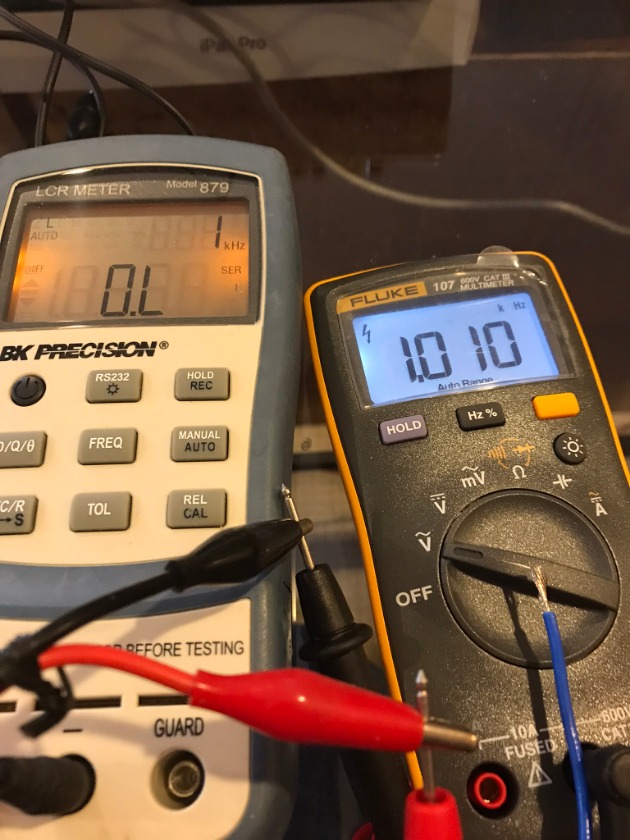

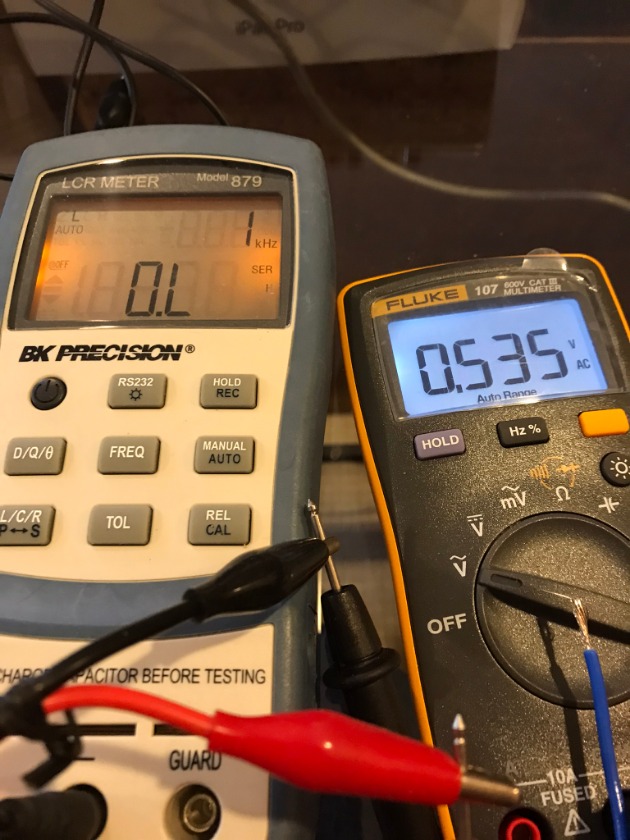

I had the time to look at the outputs of the LCR using an O-Scope and meter.

The waveform.....

Output Frequency (the manual asks for 1KHz. It can be changed to higher on the meter).....

Output voltage.....

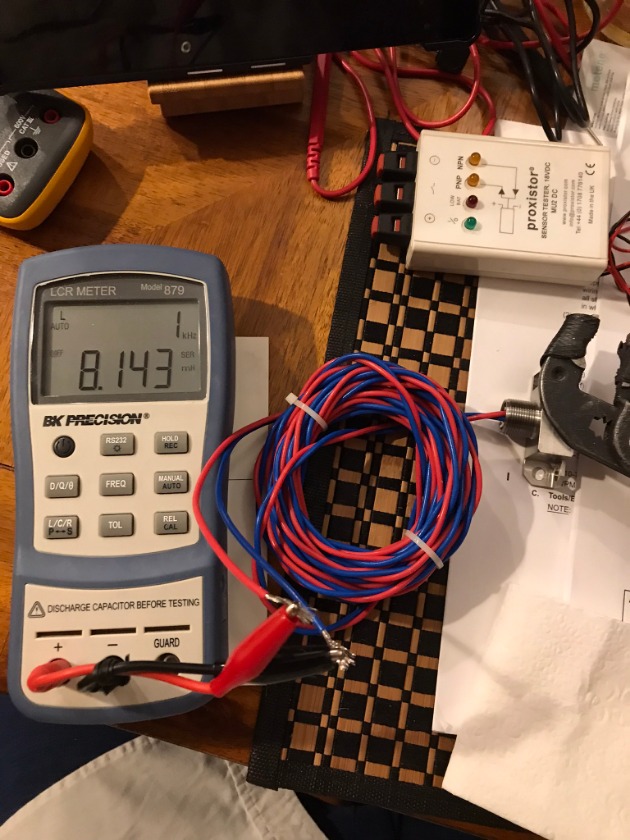

A unit called a Proxistor can also be used as a quick Fail/Pass tester on a sensor. Amazon link

here

.

This unit is really setup for three wire units (as found on some Airbus aircraft). On two wire sensors, the PNP/NPN lights should be ignored. The green light represents a good unit.