Pinned Items

Recent Activities

-

Everything seems to be working well on my end now.Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Glad you got it working, share a picture of your print once it comes out.Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

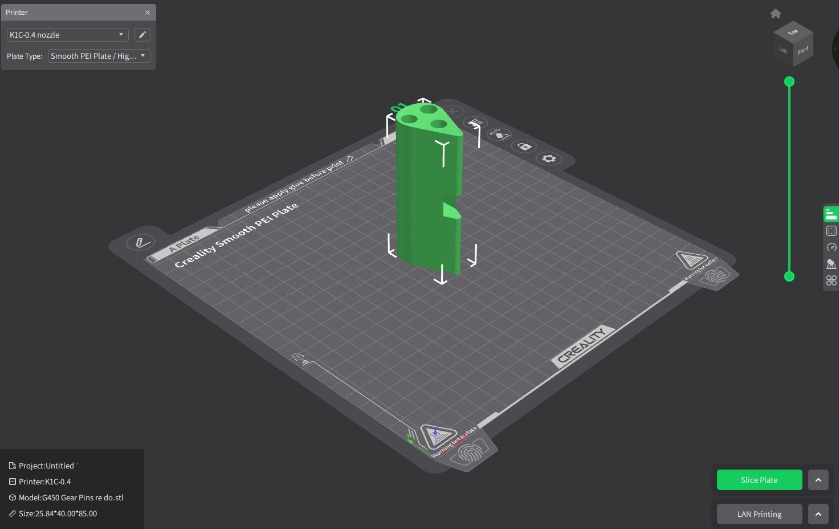

Actually after looking back in my files I had already started a new one in CAD it has dimensions as well, its slightly bigger than the one i posted above I wanted to slightly increase the size because depending on how the pins were put in they could kind of get stuck. I never finished cleaning it up but attached is another STL and Autodesk file with dimensions.Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

I think I see your issue, when I open the file in blender and Creality the model is sharp, I opened it in meshmixer and I see the odd lines and fragmented faces. I think it just comes down to the boolean operations destroying the faces. Let me know if your not able to get it to turn out I will re create it in Autodesk tomorrow.Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Try this file i re exported it after putting it in my print software, let me know if it works for you otherwise I will recreate it in autodesk instead of blender.

Post is under moderationStream item published successfully. Item will now be visible on your stream. -

Yes tomorrow I will find the orginal file and make sure its properly sized, what print software are you using?Post is under moderationStream item published successfully. Item will now be visible on your stream.

-

Probably not a PN change unless its part of a SB or AD, most probably a mod status change.

Both part numbers serve the same purposes and meet the same TCAS spec but the manufacturers and system are different the first pn is more of an all in one solution while the 2nd pn is part of the entire honeywell TCAS setup.

By no means an expert on this but I feel this should answer most of your question.Post is under moderationStream item published successfully. Item will now be visible on your stream.

There are no activities here yet