| Front Release Plugs |

||

|

Front release plugs are found on older analog based aircraft. Newer generation applications use rear release plugs for most applications. Both types of plugs use locking tabs around each pin. The tabs must be spread open for the pin to be removed.

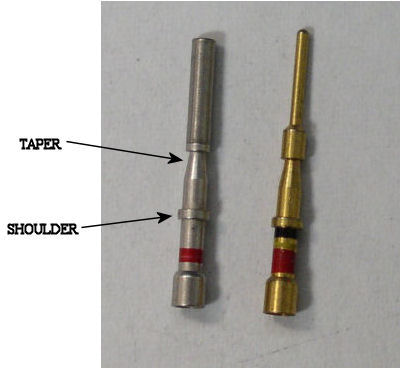

A quick visual of the front face is all that is needed to differentiate between the two. Front release will have rubber on the face and rear release will have a hard plastic material. Front release pins have a noticeable taper in diameter that starts after the shoulder.

The standard ranges of pin sizes are red, blue, and yellow. Red pins for gauges 18-22 receive the majority of use.

The most common purpose is for signal wires. The larger blue and yellow pins are found for power functions. It is not uncommon to find intermixing of pin sizes in the same plug.

Front release plugs use a pin pusher tool to remove the pins from front to back. The tools are made by several manufactures, but they all work in the same fashion.

|

|

|

|

||

|

|

|

|

Quick Notes on Front Release Plugs

Plug Numbering and Replacement

|

||

|

THE INFORMATION PRESENTED ON THIS SITE IS TO BE USED AS A GUIDE APPROVED AIRCRAFT MANUFACTURER MAINTENANCE MANUAL PROCEDURES SHOULD ALWAYS BE FOLLOWED. |

||