From theautomaticearth.com

By Raúl Ilargi Meijer

During the Senate hearing into Boeing on October 29, Senator Jon Tester told the company’s CEO Dennis Muilenburg: “I would walk before I would get on a 737 MAX. I would walk.” He added: “There is no way … You shouldn’t be cutting corners and I see corners being cut.”

That’s all fine and well, but the hearing lays bare a giant gap in US law: that of accountability. Muilenburg is the “ultimately responsible” in a chain of command that is responsible for killing 346 people. But he is still the CEO, even if he was demoted from the chairman of the board position. Which was taken over by another -10 year- veteran of the company by the way. Fresh insights galore.

If you are employed by a large company, you can sign off on such decisions, the ones that kill people, and walk away unscathed. It reminds one of Monsanto/Bayer, which just annnounced that the number of Roundup lawsuits against it went from 18,000 in July to 43,000 today. Bayer at the same time announced that its turnover rose by 6% in Q3. 43,000 lawsuits and they’re doing fine, thank you.

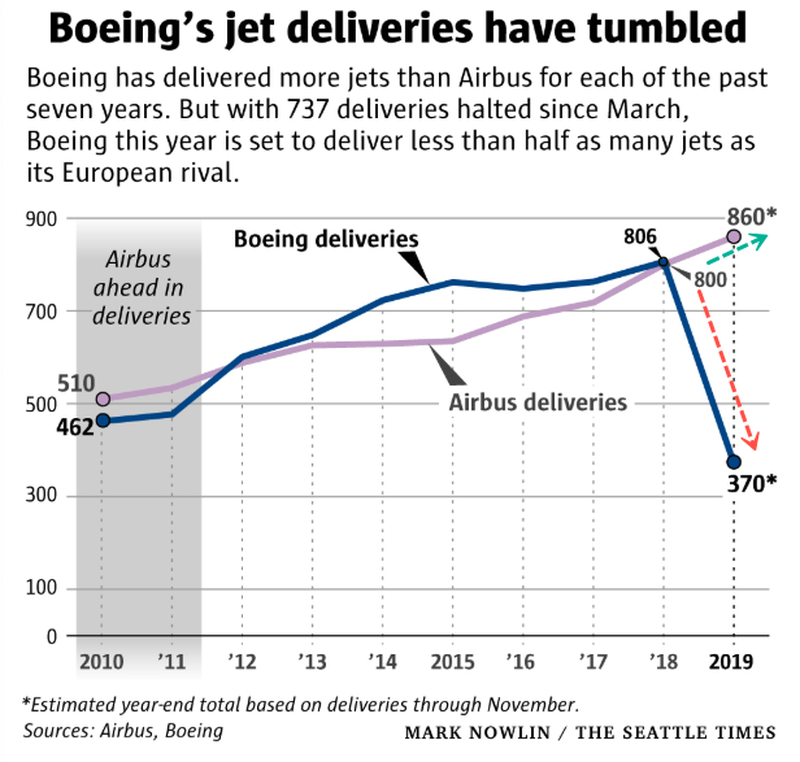

In that same vein, Boeing shares rose 2.4% last night after the hearing (“a sign investors were relieved.”) What the “investors” buying those shares may have missed is that India’s budget carrier IndiGo ordered 300 new aircraft from Airbus, at an initial cost of $33 billion -which will be subject to a juicy discount, but still-.

Now, Boeing is America’s biggest exporter. It’s also one of the cornerstones of Pentagon policy, a huge provider for the US military. So one can only expect the Senate to be lenient, to appear to be tough but let things more or less go. Still, the fact remains that Muilenburg et al made cost-cutting and other decisions that killed 346 people. But CNCB still labeled this a “brutal Senate hearing”. Yeah. Define ‘brutal’.

Maybe the thing is that those deaths were not in the US, but in Indonesia and Ethiopia. Think maybe the Senate is influenced by that? What do you think would have happened if two 737 MAX’s had fallen out of the sky in the US, even if only in deplorables’ territory? We can sort of imagine, can’t we?

And no, it’s not an all black and white picture, some people involved made some sense (via Seattle Times):

Boeing 737 MAX Should Be Grounded Until Certification Process Is ‘Reformed’ – Senator

..at least one member of the Senate committee that grilled Muilenburg on Tuesday suggested the troubled aircraft shouldn’t be flying again until a much-maligned Federal Aviation Administration (FAA) oversight program retreats from its practice of delegating authority to Boeing and other aerospace manufacturers.

Sen. Richard Blumenthal — citing revelations in recent news reports of a Boeing engineer’s claims that the MAX’s safety was compromised by cost and schedule considerations, and that the company pushed to undercut regulatory oversight — pushed back against findings that the FAA’s practice of delegating more safety certification authority is only likely to increase.

“The story of Boeing sabotaging rigorous safety scrutiny is chilling to all of us — and more reason to keep the 737 MAX grounded until certification is really and truly independent and the system is reformed,” said Blumenthal, D-Conn.

But, you know, the entire narrative is about ‘the company’, not about the people in the company who make these fatal decisions. They can do whatever they want, secure in the knowledge they will never be held to account. For financial losses perhaps at some point, but not for the loss of life. At best, they’ll get fired and walk away with a huge bonus. And that’s just wrong.

And it’s not like there were no warning signs (via Seattle Times again, from Oct 3):

Boeing Rejected 737 MAX Safety Upgrades Before Fatal Crashes – Whistleblower

Seven weeks after the second fatal crash of a 737 MAX in March, a Boeing engineer submitted a scathing internal ethics complaint alleging that management — determined to keep down costs for airline customers — had blocked significant safety improvements during the jet’s development. The ethics charge, filed by 33-year-old engineer Curtis Ewbank, whose job involved studying past crashes and using that information to make new planes safer, describes how around 2014 his group presented to managers and senior executives a proposal to add various safety upgrades to the MAX.

The complaint, a copy of which was reviewed by The Seattle Times, suggests that one of the proposed systems could have potentially prevented the crashes in Indonesia and Ethiopia that killed 346 people. Three of Ewbank’s former colleagues interviewed for this story concurred. The details revealed in the ethics complaint raise new questions about the culture at Boeing and whether the long-held imperative that safety must be the overarching priority was compromised on the MAX by business considerations and management’s focus on schedule and cost. Managers twice rejected adding the new system on the basis of “cost and potential (pilot) training impact,” the complaint states.

This one is from AP, Oct 18. These are just the most recent revelations, this stuff goes back years. Neither Boeing nor the FAA ever did anything, until the planes started falling from the skies:

Messages From Former Boeing Test Pilot Reveal 737MAX Concerns

A former senior Boeing test pilot told a co-worker that he unknowingly misled safety regulators about problems with a flight-control system that would later be implicated in two deadly crashes of the company’s 737 Max. The pilot, Mark Forkner, told another Boeing employee in 2016 that the flight system, called MCAS, was “egregious” and “running rampant” while he tested it in a flight simulator.

“So I basically lied to the regulators (unknowingly),” wrote Forkner, then Boeing’s chief technical pilot for the 737. The exchange occurred as Boeing was trying to convince the Federal Aviation Administration that MCAS was safe. MCAS was designed at least in part to prevent the Max from stalling in some situations. The FAA certified the plane without fully understanding MCAS, according to a panel of international safety regulators.

Forkner also lobbied FAA to remove mention of MCAS from the operating manual and pilot training for the Max, saying the system would only operate in rare circumstances. FAA allowed Boeing to do so, and most pilots did not know about MCAS until after the first crash, which occurred in October 2018 in Indonesia.

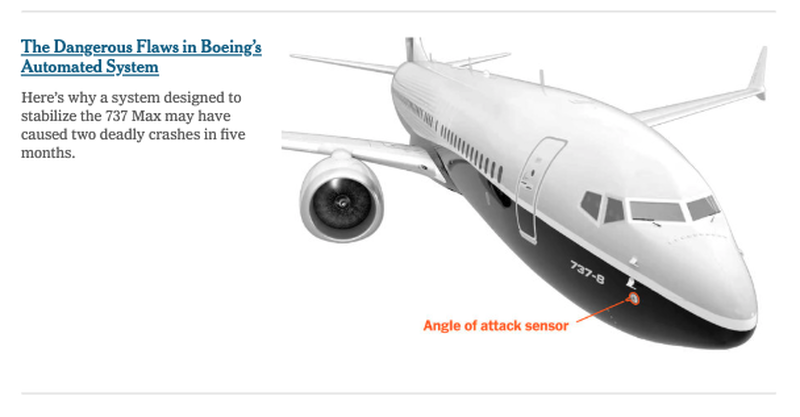

As I covered extensively before the issue at hand is that Boeing, in order to cut costs, among other things, decided to have just one -active- “angle-of-attack” sensor (which measures the angle of the plane vs income air, it’s located at the bottom front of the fuselage) on the plane. All it takes is one bird flying into it to compromise and/or deactivate that sensor. And then neither the software not the pilots know what to do anymore. But yeah, it’s cheaper… One sensor won’t do, nor will two, you need at least three in case one is defective. But yeah, that costs money. Seattle Times once again:

Messages From Former Boeing Test Pilot Reveal 737MAX Concerns

Boeing’s chief engineer for commercial airlines acknowledged that the company erred by not specifically testing the potential for a key sensor to erroneously cause software on the 737 Max to drive down the plane’s nose. In both fatal crashes, faulty data from one of two angle-of-attack sensors, which measure the pitch of the plane against the oncoming stream of air, caused the 737 Max’s Maneuvering Characteristics Augmentation System, or MCAS, to drive down the jet’s nose, which pilots struggled to counteract before ultimately entering a fatal dive.

John Hamilton, vice president and chief engineer of Boeing Commercial Airplanes, told senators that the company “did test the MCAS uncommanded inputs to the stabilizer system, due to whatever causes was driving it, not specifically due to an AOA sensor.’’ Senator Maria Cantwell of Washington, the Senate Commerce Committee’s top Democrat, asked if he now thought that was wrong. “In hindsight, senator, yes,’’ Hamilton replied.

They didn’t test the hardware at all, they tested the software! And all they have to say is that that was wrong. But only in hindsight! And then they tried to fix the mess they created with a new software program, MCAS, but didn’t even tell the pilots it existed. I kid you not! They did this because it might have required pilots to do more training, which raises the price of a plane, and they were already losing out to Airbus.

And lest we forget, this all happened because when Boeing was busy spending its capital on buying back its own shares, Airbus had developed a new plane to accommodate a much more energy-efficient -though larger- engine. When Boeing figured that out, they had neither the time nor the money left (because of the share buybacks) to develop their own new plane.

So what they did was they stuck such an engine (which they did have) onto a 737 model that was not equipped for the much bigger and heavier load. That in turn lead them to work on a software solution to lift the nose of the plane despite that load, which might have worked in theory but was always a bad idea, something in the vein of putting a giraffe’s neck on a hummingbird.

But Muilenburg and his people kept pushing it all, because they knew they had been caught awfully wanting, and they needed that more cost-efficient plane. And this is how all the ensuing mess started. It was all because of money. Of the execs being caught with their pants down, and trying to hide their naked hairy asses.

And then, as I started out this essay, they are still not held accountable. The company will face billions in ‘repair’ damages, some of them may lose their jobs or bonuses, but none will be held responsible for the deaths of those 346 people.

That is just not right. Not in the case of Monsanto, and not in that of Boeing. Not all Boeing planes are disasters, but the 737 definitely is. Donald Trump a few months ago suggested they should just rebrand the plane, give it another name, do some expensive PR work and bob’s your uncle. But let me ask you, would you fly on a 737, even if under another name? Far as I know, all they did was change the software, not the hardware.

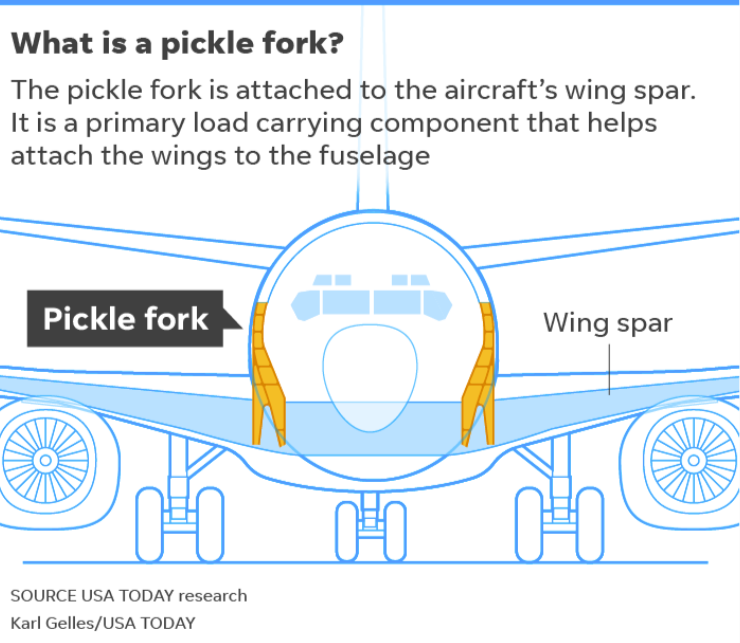

Plus, the other day some airline, was that in South Korea?!, grounded a whole bunch of 787’s because of cracks on their wings. Look, I’m not saying Boeing’s in trouble. I’m just saying Boeing’s in deep trouble. But then, you know, they’ll kick out Muilenburg and some other guys, and a few FAA heads will retire, and they’ll declare the rotten apples gone, and we’re off to a whole new start. Yay! But the 346 people will still be dead.